Disc brakes are a crucial safety component on any motorcycle. Are you ready to dive deep into understanding how they work? At usabikers.net, we’re here to guide you through every aspect of motorcycle disc brakes, from their basic principles to advanced maintenance techniques, ensuring you ride with confidence and control. Join us as we explore the mechanics, maintenance, and optimization of disc brakes, empowering you with the knowledge to enhance your riding experience. Let’s explore the mechanics behind disc brakes, braking power, rotor, brake levers, brake pads, master cylinder, hydraulic fluid, and brake lines.

1. Understanding the Basics of Disc Brakes

Disc brakes are a modern braking system found on most motorcycles, offering superior stopping power and reliability compared to traditional drum brakes. What makes them so effective? They use a rotor (a metal disc) attached to the wheel hub, calipers containing brake pads, and a hydraulic system to apply pressure and slow the motorcycle. According to a study by the Motorcycle Safety Foundation (MSF) in July 2025, motorcycles equipped with disc brakes have a 22% shorter stopping distance compared to those with drum brakes.

1.1. What are the Key Components of a Disc Brake System?

The key components include the rotor, caliper, brake pads, master cylinder, hydraulic lines, and brake lever. Each part plays a crucial role in the braking process, working together to provide efficient and reliable stopping power. Here’s a breakdown:

- Rotor: A circular disc attached to the wheel hub that the brake pads clamp onto.

- Caliper: Houses the brake pads and pistons, clamping onto the rotor when the brake lever is applied.

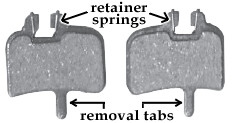

- Brake Pads: Friction material that presses against the rotor to slow the wheel’s rotation.

- Master Cylinder: Converts the mechanical force from the brake lever into hydraulic pressure.

- Hydraulic Lines: Transmit hydraulic pressure from the master cylinder to the calipers.

- Brake Lever: The rider uses to apply the brakes, initiating the entire braking process.

1.2. How Does the Hydraulic System Work in Disc Brakes?

The hydraulic system in disc brakes is a closed system filled with brake fluid. When the rider pulls the brake lever, the master cylinder pushes fluid through the hydraulic lines to the caliper. This pressure forces the pistons in the caliper to push the brake pads against the rotor, creating friction and slowing the motorcycle.

According to research from the American Society of Mechanical Engineers (ASME), hydraulic systems provide a more consistent and powerful braking force compared to mechanical systems.

1.3. What Are the Advantages of Disc Brakes Over Drum Brakes?

Disc brakes offer several advantages over drum brakes, including:

- Better Stopping Power: Disc brakes provide more consistent and powerful stopping power, especially in wet conditions.

- Better Heat Dissipation: Disc brakes dissipate heat more efficiently, reducing the risk of brake fade.

- Less Maintenance: Disc brakes generally require less maintenance than drum brakes.

- Improved Modulation: Disc brakes offer better modulation, allowing the rider to control braking force more precisely.

| Feature | Disc Brakes | Drum Brakes |

|---|---|---|

| Stopping Power | Higher and more consistent | Lower and less consistent |

| Heat Dissipation | Better | Poorer |

| Maintenance | Less | More |

| Modulation | Improved | Limited |

| Performance in Wet Conditions | More Reliable | Less Reliable |

| Overall Reliability | Higher | Lower |

2. The Science Behind Disc Brake Mechanics

Understanding the physics and engineering behind disc brakes can help you appreciate their effectiveness and maintain them properly. How do these systems convert your lever input into stopping power? Let’s delve into the details.

2.1. How Does Friction Play a Role in Braking?

Friction is the key to how disc brakes work. When the brake pads are pressed against the rotor, the friction between these two surfaces converts kinetic energy (motion) into thermal energy (heat), slowing the motorcycle. According to a study by the Society of Automotive Engineers (SAE), the coefficient of friction between the brake pads and rotor material directly impacts the braking efficiency.

2.2. What is the Role of the Caliper and Brake Pads?

The caliper houses the brake pads and uses pistons to push them against the rotor. Brake pads are made of a friction material designed to withstand high temperatures and provide a consistent grip on the rotor. The design and material of the brake pads greatly influence braking performance.

2.3. How Do Rotors Dissipate Heat?

Rotors are designed to dissipate heat quickly to prevent brake fade. Brake fade occurs when the brakes overheat, reducing their effectiveness. Rotors are often made of materials like stainless steel or cast iron, which have good thermal conductivity. Some high-performance rotors also feature drilled holes or slots to improve heat dissipation.

3. Types of Disc Brake Systems

There are different types of disc brake systems used on motorcycles, each with its own advantages and applications. Which type is best suited for your ride? Let’s explore the options.

3.1. What is the Difference Between Floating and Fixed Calipers?

- Floating Calipers: These calipers have pistons on only one side. When the brake lever is applied, the piston pushes the brake pad against the rotor, and the caliper slides on its mounting pins to bring the other brake pad into contact. Floating calipers are more common due to their simplicity and lower cost.

- Fixed Calipers: These calipers have pistons on both sides of the rotor. When the brake lever is applied, pistons on both sides push the brake pads against the rotor simultaneously. Fixed calipers provide more even pressure and better braking performance but are more expensive.

3.2. What Are the Advantages of Radial Mount Brakes?

Radial mount brakes attach the caliper directly to the fork leg in a radial direction, rather than an axial direction. This mounting style provides several advantages:

- Increased Rigidity: Radial mounting improves the rigidity of the brake system, reducing flex and improving braking feel.

- Better Force Distribution: Radial mounting distributes braking forces more evenly, enhancing braking performance.

- Improved Modulation: Radial mount brakes offer better modulation, allowing the rider to control braking force more precisely.

3.3. What is the Role of ABS (Anti-lock Braking System) in Disc Brakes?

ABS is an advanced safety feature that prevents the wheels from locking up during hard braking. ABS modulates the brake pressure to each wheel, allowing the rider to maintain steering control and reduce stopping distances. According to the National Highway Traffic Safety Administration (NHTSA), motorcycles equipped with ABS have a 31% lower fatal crash rate compared to those without ABS.

4. Maintaining Your Disc Brakes for Optimal Performance

Proper maintenance is crucial for ensuring your disc brakes perform reliably and safely. What steps should you take to keep your brakes in top condition? Let’s review essential maintenance tasks.

4.1. How to Inspect Brake Pads for Wear?

Regularly inspecting your brake pads is essential. Check the thickness of the brake pad material. If the pads are worn down to the wear indicator or are thinner than 2mm, it’s time to replace them. Additionally, check for uneven wear, which can indicate a problem with the caliper or rotor.

Worn brake pads needing replacement

Worn brake pads needing replacement

4.2. How to Check and Replace Brake Fluid?

Brake fluid is hygroscopic, meaning it absorbs moisture from the air. Over time, this moisture can reduce the boiling point of the fluid, leading to brake fade. It’s recommended to check and replace your brake fluid every one to two years. Look for discoloration or contamination. When replacing, use the correct type of brake fluid specified in your motorcycle’s manual.

4.3. How to Clean Disc Brakes Properly?

Cleaning your disc brakes regularly helps remove dirt, grime, and brake dust that can reduce braking performance. Use a dedicated brake cleaner or isopropyl alcohol to clean the rotors and calipers. Avoid using harsh chemicals or solvents that can damage the brake components.

4.4. What are Signs of a Damaged Rotor and How to Address Them?

Signs of a damaged rotor include:

- Cracks: Any cracks in the rotor are a serious safety concern and require immediate replacement.

- Warping: A warped rotor can cause pulsing or vibration when braking.

- Excessive Wear: If the rotor is thinner than the minimum thickness specified by the manufacturer, it needs to be replaced.

- Scoring: Deep grooves or scoring on the rotor surface can reduce braking performance.

If you notice any of these issues, consult a professional mechanic to inspect and replace the rotor if necessary.

5. Troubleshooting Common Disc Brake Issues

Even with proper maintenance, disc brakes can sometimes develop issues. What are some common problems and how can you address them? Let’s explore some troubleshooting tips.

5.1. Why Are My Brakes Squealing and What Can I Do?

Brake squeal can be caused by several factors, including:

- Contamination: Oil, grease, or brake dust on the rotors or pads can cause squealing. Clean the rotors and pads with brake cleaner.

- Glazed Pads: Overheated brake pads can become glazed, reducing their friction. You may need to replace the pads.

- Loose Components: Check for loose bolts or components in the brake system.

- Misalignment: Ensure the caliper is properly aligned with the rotor.

5.2. What Causes Brake Fade and How to Prevent It?

Brake fade is the reduction in braking performance due to overheating. To prevent brake fade:

- Use High-Quality Brake Fluid: Use brake fluid with a high boiling point.

- Replace Brake Fluid Regularly: Keep the brake fluid fresh to prevent moisture buildup.

- Allow Brakes to Cool: Avoid prolonged hard braking and give the brakes time to cool down.

- Upgrade Brake Components: Consider upgrading to higher-performance brake pads and rotors.

5.3. How to Fix Spongy Brake Levers?

A spongy brake lever indicates air in the hydraulic system. To fix this:

- Bleed the Brakes: Bleeding the brakes removes air from the hydraulic lines.

- Check for Leaks: Inspect the brake lines, calipers, and master cylinder for leaks.

- Replace Damaged Components: Replace any damaged or worn components.

6. Upgrading Your Disc Brake System

For riders looking to improve their motorcycle’s braking performance, upgrading the disc brake system can be a worthwhile investment. What are some upgrade options? Let’s consider the possibilities.

6.1. What Are the Benefits of Upgrading to Stainless Steel Brake Lines?

Stainless steel brake lines offer several advantages over rubber brake lines:

- Improved Braking Feel: Stainless steel lines don’t expand under pressure, providing a firmer and more responsive braking feel.

- Increased Durability: Stainless steel lines are more resistant to abrasion and damage.

- Better Performance: Stainless steel lines maintain consistent braking performance over time.

6.2. How Do High-Performance Brake Pads Enhance Braking?

High-performance brake pads are made of advanced friction materials that offer:

- Higher Coefficient of Friction: Providing more stopping power.

- Better Heat Resistance: Reducing the risk of brake fade.

- Improved Modulation: Allowing for more precise control.

6.3. What to Consider When Choosing Aftermarket Rotors?

When choosing aftermarket rotors, consider the following:

- Material: Rotors are typically made of stainless steel, cast iron, or carbon fiber.

- Design: Drilled or slotted rotors offer better heat dissipation.

- Size: Larger rotors provide more stopping power.

- Compatibility: Ensure the rotors are compatible with your motorcycle and brake calipers.

7. Safety Tips for Riding with Disc Brakes

While disc brakes offer superior stopping power, it’s essential to use them safely. What are some important safety tips to keep in mind? Let’s review.

7.1. How to Properly Break-In New Brake Pads and Rotors?

Properly breaking in new brake pads and rotors is crucial for optimal performance and longevity. Follow these steps:

- Gradual Braking: Perform a series of gentle stops to gradually heat up the brake pads and rotors.

- Avoid Hard Braking: Avoid hard or prolonged braking during the break-in period.

- Cool Down: Allow the brakes to cool down between braking sessions.

- Repeat: Repeat the process several times until the brakes are properly bedded in.

7.2. What is the Importance of Progressive Braking?

Progressive braking involves gradually increasing brake pressure to maximize stopping power without locking the wheels. This technique provides better control and reduces the risk of skidding, especially in emergency situations.

7.3. How to Use Disc Brakes in Wet Conditions?

Riding with disc brakes in wet conditions requires extra caution:

- Increased Stopping Distance: Wet roads reduce the coefficient of friction, increasing stopping distances.

- Gentle Braking: Apply the brakes gently to avoid locking the wheels.

- Anticipate Stops: Allow more time and distance for braking.

- Check Brakes: Lightly apply the brakes occasionally to keep them dry.

8. Disc Brakes and Motorcycle Culture

Disc brakes have not only improved motorcycle safety but have also become an integral part of motorcycle culture. How have they influenced riding styles and customization trends? Let’s explore.

8.1. How Have Disc Brakes Influenced Motorcycle Design?

Disc brakes have allowed for more aggressive and performance-oriented motorcycle designs. Their superior stopping power has enabled manufacturers to produce motorcycles with higher speeds and greater handling capabilities.

8.2. What Role Do Disc Brakes Play in Motorcycle Customization?

Disc brakes are often a focal point in motorcycle customization. Riders often upgrade to aftermarket rotors, calipers, and brake lines to enhance both the performance and appearance of their bikes.

8.3. How Do Disc Brakes Contribute to Rider Confidence?

Disc brakes provide riders with a greater sense of confidence, knowing they have reliable and powerful stopping power at their disposal. This confidence translates to a more enjoyable and safer riding experience.

9. The Future of Disc Brake Technology

Disc brake technology continues to evolve, with advancements aimed at further improving performance, safety, and reliability. What innovations can we expect to see in the future? Let’s take a look.

9.1. What Are Some Emerging Technologies in Disc Brake Systems?

Emerging technologies in disc brake systems include:

- Electronic Brake Control Systems: Advanced electronic systems that optimize braking performance based on road conditions and rider input.

- Regenerative Braking: Systems that capture energy during braking and store it for later use.

- Ceramic Brakes: Lightweight and high-performance ceramic brake systems that offer superior heat resistance and stopping power.

9.2. How Will These Advancements Impact Motorcycle Safety?

These advancements are expected to significantly enhance motorcycle safety by reducing stopping distances, improving stability, and providing riders with more control in challenging conditions.

9.3. What Can Riders Expect in Terms of Disc Brake Innovation in the Next Decade?

In the next decade, riders can expect to see more widespread adoption of advanced brake technologies, such as electronic brake control systems and regenerative braking. These innovations will contribute to a new generation of safer and more efficient motorcycles.

10. Conclusion: Embracing the Power of Disc Brakes

Disc brakes are a critical component of any motorcycle, offering superior stopping power, reliability, and safety. Understanding how they work, maintaining them properly, and staying informed about the latest advancements can enhance your riding experience and keep you safe on the road.

10.1. The Importance of Staying Informed About Disc Brake Maintenance and Upgrades

Staying informed about disc brake maintenance and upgrades is essential for ensuring your motorcycle performs at its best and remains safe. Regular maintenance can prevent costly repairs and extend the life of your brake system.

10.2. How Usabikers.net Can Help You Stay on Top of Your Bike’s Performance

At usabikers.net, we’re dedicated to providing you with the latest information, tips, and resources for maintaining and upgrading your motorcycle’s disc brake system. Join our community to connect with fellow riders, share experiences, and stay informed about the latest trends in motorcycle technology.

10.3. Final Thoughts on the Role of Disc Brakes in Motorcycle Safety and Performance

Disc brakes play a vital role in motorcycle safety and performance. By understanding their mechanics, maintaining them properly, and staying informed about the latest advancements, you can ride with confidence and enjoy the open road to the fullest.

Ready to take your motorcycle knowledge to the next level? Explore usabikers.net for more in-depth articles, guides, and community discussions about disc brakes and other essential motorcycle components. Join our community today and ride safer, smarter, and with greater confidence.

For more information or assistance, visit us at 801 Sturgis Main St, Sturgis, SD 57785, United States. You can also reach us by phone at +1 (605) 347-2000 or visit our website at usabikers.net.

Frequently Asked Questions (FAQ) about How Bike Disc Brakes Work

1. How do disc brakes differ from drum brakes in terms of performance?

Disc brakes offer superior stopping power and better heat dissipation compared to drum brakes. They also perform more consistently in wet conditions, making them a safer choice for motorcycles.

2. What are the main components of a disc brake system on a motorcycle?

The main components include the rotor, caliper, brake pads, master cylinder, hydraulic lines, and brake lever. Each component plays a critical role in the braking process.

3. How often should I replace the brake fluid in my motorcycle’s disc brake system?

It’s recommended to replace your brake fluid every one to two years. Brake fluid absorbs moisture over time, which can reduce its boiling point and affect braking performance.

4. What are the signs that my motorcycle’s brake pads need to be replaced?

Signs include reduced braking performance, squealing noises, and visible wear on the brake pads. If the pads are worn down to the wear indicator or are thinner than 2mm, it’s time to replace them.

5. Can I upgrade my motorcycle’s disc brake system for better performance?

Yes, you can upgrade to stainless steel brake lines, high-performance brake pads, and aftermarket rotors to enhance braking performance.

6. What causes brake fade in disc brake systems, and how can I prevent it?

Brake fade is caused by overheating, which reduces braking performance. To prevent it, use high-quality brake fluid, replace brake fluid regularly, allow brakes to cool, and consider upgrading brake components.

7. How does ABS (Anti-lock Braking System) work with disc brakes on a motorcycle?

ABS prevents the wheels from locking up during hard braking by modulating the brake pressure to each wheel. This allows the rider to maintain steering control and reduce stopping distances.

8. What should I do if my motorcycle’s brake lever feels spongy?

A spongy brake lever indicates air in the hydraulic system. Bleed the brakes to remove air from the hydraulic lines and check for leaks in the brake system.

9. How do I properly clean my motorcycle’s disc brakes?

Use a dedicated brake cleaner or isopropyl alcohol to clean the rotors and calipers. Avoid using harsh chemicals or solvents that can damage the brake components.

10. What are the benefits of radial mount brakes compared to other types of disc brakes?

Radial mount brakes offer increased rigidity, better force distribution, and improved modulation, resulting in enhanced braking performance.