Like many car and motorcycle enthusiasts, I have my quirks. Naming vehicles or ascribing human traits to them isn’t really my thing. However, when faced with a truly stubborn project, like my Honda XR600R dirt bike, I’ve found myself resorting to some unconventional methods. Treating this recalcitrant machine as a dog in need of training? Surprisingly, it helped.

You might be rolling your eyes, thinking, “Another article about the bike that refuses to start? Why can’t this guy just give up?” And honestly, I get it. The thought has crossed my mind numerous times over the past few weeks. But I keep coming back to this Honda Dirt Bike because I’m determined to learn from my mistakes. I was foolishly optimistic, thinking that starting and breaking in this engine would be a walk in the park. The tuning issues that have emerged are a well-deserved lesson in humility.

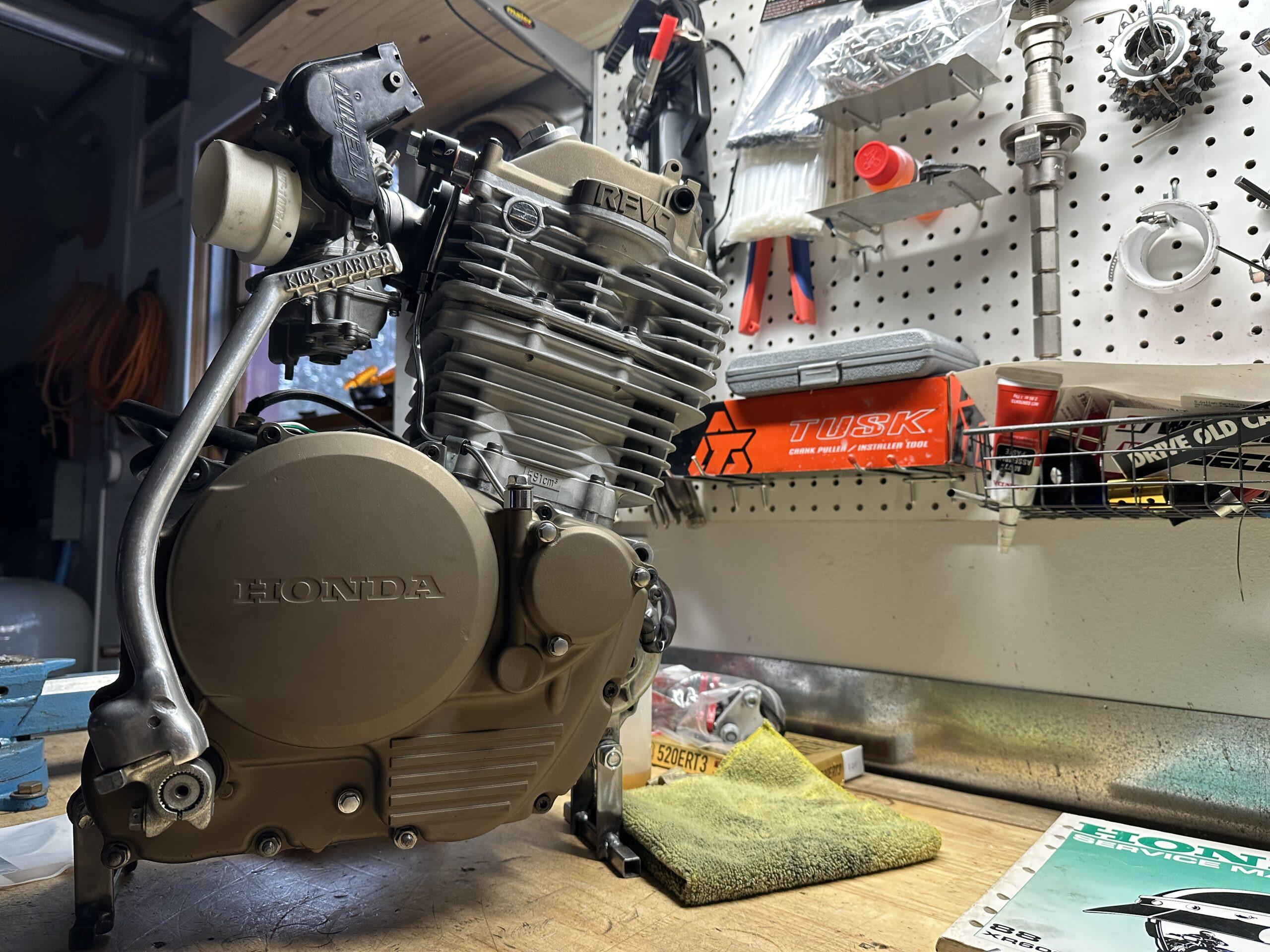

The XR600R, this legendary Honda dirt bike, is essentially a collection of parts held together by a multitude of M6 bolts. Assembled according to the manual, there’s no logical reason it shouldn’t run perfectly. Except, of course, for all the modifications I made. This engine arrived in 14 boxes, and as I meticulously rebuilt it, I couldn’t resist making a few “improvements.” A new camshaft with a non-factory grind? Absolutely. A large Keihin FCR41 carburetor? Who could resist?

A wiser person, that’s who.

honda XR600R on workbench

honda XR600R on workbench

Diagnosing a newly assembled project is challenging enough. Learning the specific needs and quirks of this mechanical beast was already complex under ideal circumstances. Over the course of this Honda dirt bike engine rebuild, I modified so many components that I was forced to return to the most fundamental principles of diagnostics: fuel, air, and spark. It turned out I was battling an air issue disguised as a fuel problem. For three consecutive weekends, I wrestled with, removed, rebuilt, cleaned, re-cleaned, stared at, cursed at, and ultimately disassembled the FCR carb for the third time. My mission? To understand why a device designed for precise air-fuel mixing was delivering an extra dose of air.

XR600R carb rebuild 10 fuel bottle

XR600R carb rebuild 10 fuel bottle

I was able to coax the big thumper to run by drastically adjusting the mixture screw, essentially feeding it as much fuel as the pilot jet could manage. Even then, the engine would sputter and backfire through the carburetor, indicating an excessively lean condition. After meticulously checking and re-checking for vacuum leaks, and even crafting a custom O-ring for the carb, the solution finally emerged: plugging the hot-start mechanism with silicone. Only then did the carburetor begin metering air correctly. This entire ordeal became so frustrating that, in the depths of a dreary February, I gave in and started talking to the bike as if it could understand me. Coaxing turned into pleading, as if the engine would somehow communicate its needs.

When that yielded no results, I shoved the half-assembled motorcycle into the garage corner and tried to forget about the whole problem. Then, a strange idea took hold. Sometimes in dog training, when faced with a particularly stubborn canine, instructors bring in a well-behaved example. I needed an older, wiser “pup” that spoke the same mechanical language as the XR600R and was already on my side. So, I visited a friend and borrowed his trusty Honda XR200R dirt bike. I placed it on the lift, made a few adjustments, and had it running smoothly after a basic tune-up. Throughout the process, I kept glancing at the sulking XR600R, as if to say, “This could be you. Look how easily it gets to play in the driveway and even cruise around the neighborhood, regardless of the weather—all because it chooses to cooperate.”

Bowen XR200R on lift

Bowen XR200R on lift

The most absurd part of this whole scenario? It actually worked. After leaving the XR600R untouched in the corner for a week, my motivation to try again returned. I followed the starting procedure: Carefully rotate the engine to top dead center on the compression stroke, use the compression release to move the piston past TDC, reset the kickstarter, and kick with conviction.

On the third attempt, the engine responded to the force of my kick, drawing air through the flat-slide carb, igniting the fuel, and expelling hot exhaust. It settled into a high but consistent idle. After about ten seconds, I engaged the choke, reducing the extra fuel for cold starts and lowering the engine to a smoother, slower idle. The deep thumping sound from the exhaust was both powerful and delicate. Before that day, the bike had never idled correctly. Even in this moment of triumph, a nagging doubt lingered – was everything truly fixed?

Kyle Smith garage feb 2025

Kyle Smith garage feb 2025

Who knows for sure? Without further testing, I’m still uncertain which specific action was the magic bullet. There’s a point where I almost stop caring why it worked. I made the final two adjustments – sealing the hot start and adjusting the fuel screw – simultaneously, a less-than-ideal, shotgun approach. This leaves me wondering which adjustment was truly effective and which was simply a placebo.

Regardless, the engine now runs, and I can finally shift my focus to removing it from the frame and starting on the finishing touches and final assembly. Spring is approaching rapidly, and it would be fantastic to get in some test miles ahead of schedule. From my current perspective, this hurdle feels like the highest peak I’ll have to climb in this Honda dirt bike project. But then again, I initially thought this engine was just a collection of parts that would work flawlessly if assembled correctly. This bike, however, is proving to have far more character than that.