All too often, cyclists are seen pedaling frantically or struggling uphill, barely moving forward. Properly using Bike Gears can significantly improve the riding experience for these individuals.

This guide offers a complete overview of bicycle gears, explaining what they are and how to effectively use them on your bike.

What are Bike Gears?

Close-up of Ultegra R8000 rear derailleur and cassette showing gear detail

Close-up of Ultegra R8000 rear derailleur and cassette showing gear detail

Bike gears are essential for efficient cycling. Gears are ingenious mechanisms that allow cyclists to ride faster, climb hills with less effort, and ultimately enjoy their rides more.

They function by converting the force applied to the pedals into varying levels of output at the wheel. Human muscle power has limitations, and there’s generally an optimal cadence (pedal spinning rate) for peak efficiency.

Adjusting your bike gears in response to changes in terrain and riding conditions, aiming to maintain that efficient cadence range, allows for more effective forward motion.

While several gear-shifting systems exist for bicycles, derailleur gears are by far the most prevalent.

Derailleur Gears: How They Work

External bike drivetrain with front and rear derailleurs and chainrings

External bike drivetrain with front and rear derailleurs and chainrings

Derailleur gears are the standard on most modern bikes. The majority of bikes available today utilize derailleur gears, which have evolved into streamlined, lightweight, and highly efficient systems.

Gear changes are executed on the cassette (the set of sprockets on the rear wheel) by the rear derailleur. The rear derailleur’s role is to move the chain up or down the cassette sprockets. As the derailleur shifts, it guides the chain against specifically designed ramps or steps on the sprockets, causing it to move to a larger or smaller sprocket.

Many bikes also incorporate a front derailleur, responsible for shifting the chain between the chainrings, which are components of the crankset.

Front derailleur shifts produce larger gear changes, primarily altering the overall gear range for situations like high-speed riding on flat ground or low-speed hill climbing. The rear cassette allows for finer gear adjustments within that broader range, enabling precise modulation of effort.

Typically, you’ll find one to three chainrings at the front (categorized as single, double, or triple cranksets) and up to 12 sprockets on the rear cassette (with 13-speed options emerging, such as Campagnolo Ekar and Rotor 1×13). This configuration offers a wide spectrum of gear choices.

Internal Gear Hubs: An Alternative Gearing System

Shimano Alfine 11-speed internal gear hub with Gates Carbon Drive belt

Shimano Alfine 11-speed internal gear hub with Gates Carbon Drive belt

Internal gear hubs (also known as hub gears) are a favored choice for commuters and cyclists seeking a durable and relatively low-maintenance drivetrain.

With recommended service intervals ranging from 3,000 to 5,000km, internal gear hubs appeal to those who prefer minimal maintenance.

Derailleurs are also somewhat exposed and prone to damage. Encasing the gearing system within the rear wheel hub provides added protection, especially during harsh winter conditions when safeguarding gears from the elements is beneficial.

Numerous hub gear options are available, with Shimano, SRAM, Sturmey-Archer, and Rohloff being prominent manufacturers.

Systems range from three to 14 gears, providing a broad selection for diverse terrains.

However, a primary disadvantage is weight. Essentially, you’re carrying a small gearbox within the hub, which contains numerous metal components, adding considerable weight.

Puncture repairs can also be more complicated with hub gears.

Gearbox Bikes: Centralized Gearing

Pinion gearbox integrated into a mountain bike frame

Pinion gearbox integrated into a mountain bike frame

A drawback of hub gears is the concentrated weight at the rear wheel, potentially affecting bike handling balance.

Gearboxes address this by integrating directly into the bike frame, positioning the weight centrally. The crankset drives the gears directly, and the output is managed within the gearbox before being transmitted to the rear wheel via a chain.

The Pinion E-Drive Motor Gearbox unit represents a significant recent advancement. Despite these innovations, gearboxes remain a niche technology in the cycling world.

Gates Carbon Drive belt on a bicycle drivetrain

Gates Carbon Drive belt on a bicycle drivetrain

Both gearboxes and hub gears are compatible with belt drives. Belt drives require even less upkeep than chains, eliminating the need for lubrication and offering a cleaner alternative to oily chains.

However, belt drives are frame-dependent. Due to the belt’s continuous loop design, compatible frames need separable dropouts or a chainstay splitter to allow belt insertion into the rear triangle.

Electronic Groupsets: Digital Gear Shifting

Shimano Ultegra R8100 Di2 electronic front derailleur

Shimano Ultegra R8100 Di2 electronic front derailleur

Most bike gears today are cable-actuated using Bowden cables.

Electronic groupsets have been available for some time and are becoming increasingly prevalent.

Instead of cables, gear changes are executed by an electronically controlled motor. The primary advantage is consistent shifting performance. While cables can develop slack and stretch over time, electronic drivetrains maintain precise shifting in all conditions.

The downsides include the need to recharge batteries (though not frequently) and the higher cost, although prices are gradually decreasing.

SRAM Rival eTap AXS wireless rear derailleur

SRAM Rival eTap AXS wireless rear derailleur

Shimano, Campagnolo, and SRAM all offer electronic groupsets. SRAM’s AXS ecosystem and Campagnolo Super Record Wireless eliminate wires between derailleurs entirely.

Shimano’s Di2 system is semi-wireless, using a wireless connection between shifters and derailleurs but retaining wires to connect front and rear derailleurs to the battery.

Singlespeed and Fixed Gear Bikes: Simplicity in Motion

Surly Steamroller singlespeed gravel bike

Surly Steamroller singlespeed gravel bike

Choosing a single gear is always an option, reflecting cycling’s origins.

Singlespeed bikes use a single cog that allows freewheeling, enabling the rear wheel to rotate without pedal movement.

Fixed-gear bikes (fixies) are even more basic, with the rear cog fixed to the wheel. This means when the bike moves, the drivetrain moves, requiring continuous pedaling.

The primary benefits are simplicity, minimal maintenance, and lower cost. Singlespeeds have also gained popularity as a style choice.

The key to singlespeed riding is selecting a gear ratio that’s easy enough for the steepest anticipated hills but hard enough to avoid excessive spinning on faster sections.

How to Use Bike Gears Effectively

Cyclist riding Nukeproof Digger RS V3 gravel bike, demonstrating gear use

Cyclist riding Nukeproof Digger RS V3 gravel bike, demonstrating gear use

Having bike gears is only useful if you know how to use them. Various shifter designs exist, each operating slightly differently, but they become intuitive with practice.

Front and rear shifters are separate and typically located on the left and right sides of the handlebars, respectively.

Flat Bar and Mountain Bike Shifters

Flat handlebars are common on hybrid, commuting, and mountain bikes. Several shifter types are available for flat bars.

Trigger Shifters

Trigger shifters on a Specialized Sirrus commuter bike handlebar

Trigger shifters on a Specialized Sirrus commuter bike handlebar

Trigger shifters are now the most prevalent design. They feature two levers positioned under the handlebar, operated by thumbs or fingers: one for upshifts and one for downshifts.

Depending on the specific design, trigger shifters may allow for multiple gear changes at once. Shimano also offers designs integrating shifter and brake levers into a single unit.

Grip Shifters

Grip shift shifter on a Pinion gearbox bicycle

Grip shift shifter on a Pinion gearbox bicycle

Grip shifters enable rapid multiple gear changes, unlike trigger shifters which typically shift one gear at a time.

Grip shifters are integrated into the handlebar grip. Gears are changed by twisting the shifter, similar to a motorcycle throttle.

Thumb Shifters

Old-style thumb shifter on a bicycle handlebar

Old-style thumb shifter on a bicycle handlebar

Though less common now, thumb shifters still appear occasionally.

A lever on top of the handlebars is moved clockwise or counter-clockwise to cycle through gears.

Modern gears are indexed, meaning each click on the shifter corresponds to a defined gear change.

Older shifters lacked this indexing and relied on friction to hold position, requiring continuous adjustment until the gear changed. These friction thumb shifters may still be encountered on older bikes.

Road Bike Shifters

Road bike shifters integrated into brake levers on drop handlebars

Road bike shifters integrated into brake levers on drop handlebars

Drop handlebars are found on road bikes designed for speed rather than maximum comfort. Road bikes also utilize various shifter designs.

For detailed information, refer to our separate guide on how to use road bike shifters.

Understanding How Bike Gears Work

Gear Inches Explained

Bike gears translate your pedaling effort into wheel rotation. Cadence (pedaling speed) is converted into different speeds at the rear wheel, depending on whether you are in a high or low gear.

Gear development, or how far your bike travels per pedal stroke, is commonly measured in gear inches. This represents the distance in inches your bike moves forward with each full crank rotation.

Online calculators are available to determine gear inches based on wheel size, tire size, and chainring/sprocket sizes.

Gear inches provide a helpful indication of gear difficulty, with approximately 20 inches being very easy, 70 inches being medium, and over 100 inches being quite hard.

Gear Range and Ratios

Close-up of a Wilier Zero SLR road bike cassette showing sprocket sizes

Close-up of a Wilier Zero SLR road bike cassette showing sprocket sizes

Gear range is often expressed as a percentage, describing the total range of gear ratios offered by the system. A 300 percent range, for example, indicates a 3:1 ratio. In the highest gear, each pedal stroke moves you three times further than in the lowest gear.

For external drivetrains, gear range is calculated by multiplying the ratio of the largest and smallest chainring teeth by the ratio of the largest and smallest cassette sprocket teeth.

Cassette specifications are usually given as the smallest and largest sprocket sizes. An 11-28t cassette indicates sprockets ranging from 11 teeth (smallest) to 28 teeth (largest).

Road bike cranksets come in various configurations, including standard, compact, super-compact, and triple.

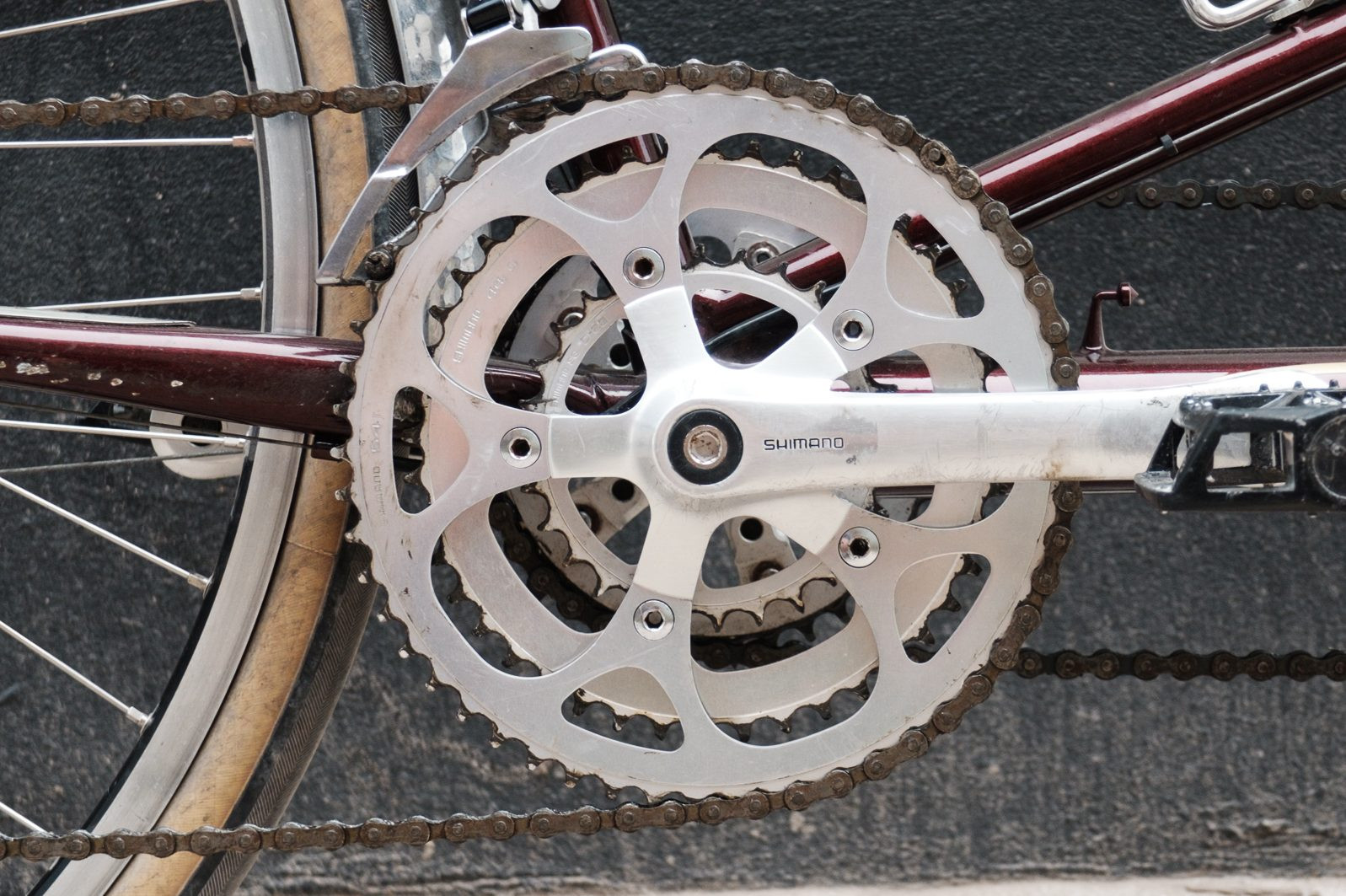

Triple crankset with three chainrings on a bicycle

Triple crankset with three chainrings on a bicycle

Triple cranksets, once common, are now primarily found on touring bikes or bikes designed for very hilly terrain requiring a wide gear range.

Double chainring cranksets are more common today, offered in standard or compact configurations, typically with 53/39t, 52/36t, or 50/34t chainring combinations. Standard cranksets are better suited for high-speed riding due to their larger chainrings.

Compact cranksets offer a wider range and slightly easier gearing, making them versatile for general riding, including both speed and hill climbing.

Super-compact cranksets, with even lower gear ratios than compact versions, are also available for enhanced climbing performance.

SRAM NX Eagle 1x drivetrain on a full suspension mountain bike

SRAM NX Eagle 1x drivetrain on a full suspension mountain bike

Mountain bike cranksets typically use even smaller chainrings to handle steep inclines and off-road conditions. Single chainring (1x) setups are now standard on most mountain bikes and many gravel bikes.

These 1x systems are generally paired with wide-range cassettes.

To calculate the total number of gears, multiply the number of front chainrings by the number of rear cassette sprockets.

However, the ‘number of gears’ can be misleading, as some gear ratios may be duplicated across different chainring/sprocket combinations. Furthermore, certain gear combinations should be avoided due to excessive chain angles.

For gear hubs and gearboxes, manufacturers usually specify the total gear range as a percentage. For example, a 14-speed Rohloff hub has a 526 percent range, while a Pinion P1.12 gearbox boasts a 600 percent range.

Selecting the Right Bike Gear

Efficient cycling is all about effective gear use.

Imagine trying to climb a steep hill in a high gear. You’d have to exert tremendous force on the pedals and struggle your way uphill.

In contrast, a lower gear reduces the force needed at the pedals, allowing you to spin them faster.

In both cases, your energy expenditure is roughly the same. Work is defined as force multiplied by distance. Halving the required force means pedaling twice as fast to maintain the same work output.

However, there’s a limit to the force your legs can generate (and your knees can tolerate). At this point, shifting to a lower gear becomes preferable to reduce the force needed and increase cadence.

Knee strain is a crucial consideration. It’s much easier on your body to pedal with lighter force at a higher cadence than to grind along with high force at a low cadence.

Conversely, spinning too quickly becomes inefficient and can even destabilize you. Shifting to a higher gear reduces your cadence in such situations.

You’ll quickly develop a feel for optimal gear selection. The goal is to balance pedal force and cadence, avoiding excessive force or spinning, and enabling smooth pedaling. The ideal cadence is subjective but often falls within the 70 to 100 rpm range.

When to Shift Gears on Your Bike

Mountain biker in camouflage riding a Bergamont Contrail Pro full suspension bike uphill

Mountain biker in camouflage riding a Bergamont Contrail Pro full suspension bike uphill

Anticipation is key to effective gear shifting. Look ahead and predict changes in speed and necessary gear adjustments.

Approaching a tight corner? Anticipate slowing down and shift to a lower gear for easier acceleration out of the turn.

Riding uphill or into a headwind? Increased effort signals the need to shift to a lower gear.

Stopping at traffic lights? Shift to an easier gear for easier starts when the light turns green.

A major mistake to avoid with external drivetrains is shifting while stationary. Always pedal while shifting to ensure smooth gear changes and shift progressively through the gear range to find the right gear.

Cross-chaining should also be avoided. With multiple chainrings, avoid small-small or large-large chainring-sprocket combinations.

Extreme chain angles from cross-chaining can increase drivetrain wear and stress.

In contrast, hub gears and gearboxes can typically be shifted at a standstill. In fact, they are often sensitive to shifting under load, so briefly easing pressure on the pedals while shifting is helpful.

Maintaining Your Bike Drivetrain

Close-up of a dirty bicycle chain and cassette

Close-up of a dirty bicycle chain and cassette

Keeping your gears clean and maintained is crucial for optimal performance. Regular bike cleaning, in general, aids in maintenance and allows early detection of potential problems before they escalate.

Hub gears are generally lower maintenance, though cable tension adjustments may be needed over time due to cable stretch.

Routine maintenance is beneficial long-term, as a well-maintained bike is gentler on its components.

We offer guides on how to adjust bike gears and how to adjust a rear derailleur.

Regular chain cleaning, including degreasing and lubrication, is also essential.

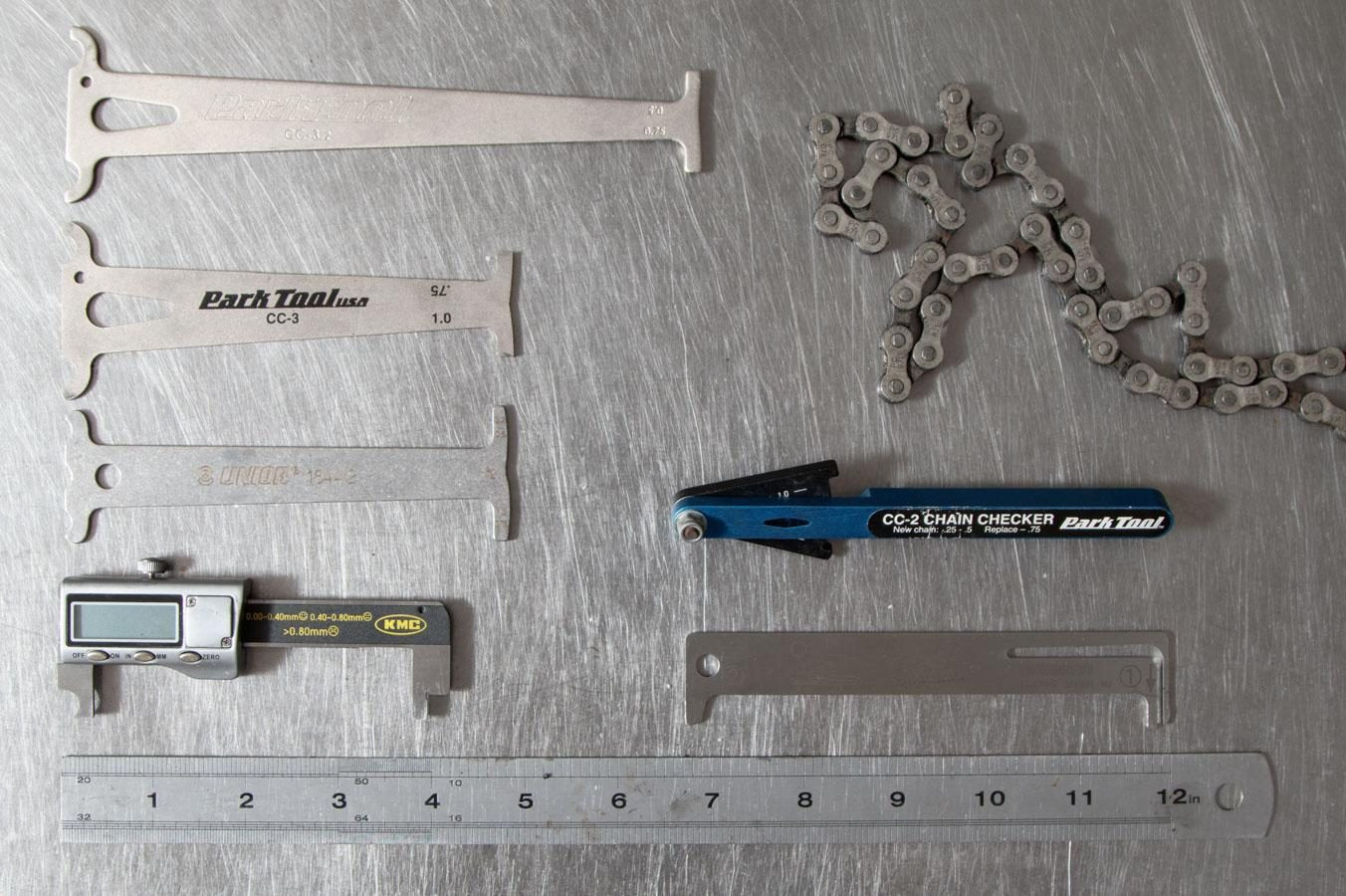

Cyclist using a chain wear checker tool on a bicycle chain

Cyclist using a chain wear checker tool on a bicycle chain

Regularly check your chain for wear using a chain checker tool. Replacing a worn chain is significantly less expensive than replacing other drivetrain components damaged by a worn chain.

With this knowledge, get out and use your bike gears effectively. You’ll be conquering hills effortlessly in no time!