The rugged, post-apocalyptic world of “The Walking Dead” is as much about survival as it is about iconic imagery. Among the most recognizable symbols of resilience and resourcefulness is Daryl Dixon’s motorcycle. This isn’t just any bike; it’s a custom-built machine that perfectly embodies Daryl’s character – tough, practical, and undeniably cool. From the moment it first appeared on screen, I, like many fans and bike enthusiasts, was captivated. Moving beyond just admiration, I decided to embark on a journey to recreate this legendary motorcycle as closely as possible. My goal? A near 1:1 replica of Daryl’s unforgettable ride.

Side profile illustration of Daryl's motorcycle build components

Side profile illustration of Daryl's motorcycle build components

Initially, cafe racers weren’t really my style. But Daryl’s bike was different. It possessed a raw, aggressive aesthetic that transcended typical cafe racer conventions. Driven by this fascination, I started a deep dive to uncover everything about this machine: its origins, the base bike, and the modifications that made it Daryl’s signature ride. Thankfully, Classified Moto, the masterminds behind the original build, provided a build sheet on their website, outlining the key components. The magic of Daryl’s bike lies in its ingenious blend of parts from three distinct motorcycles:

- The Foundation: 1992 Honda Nighthawk 750

- The Front End Upgrade: 2008-2014 Yamaha YZF-R6

- The Classic Touches: Yamaha XS650 Standard (estimated 1977 model)

The First Milestone: Acquiring the Nighthawk 750

The hunt began for the heart of the build: a 1992 Honda Nighthawk 750. For authenticity, sticking to the ’92 model was crucial. This search spanned months, but persistence paid off. I located a potential candidate in Orlando. The seller mentioned it hadn’t run in a month, a common sign of carburetor issues. Upon inspection, the bike showed signs of a front-end incident (broken turn signals), aftermarket exhaust, and the non-starting engine. While these weren’t ideal, the core of the bike was there, and crucially, these issues were related to parts that were slated for replacement anyway in the Daryl bike conversion. However, the initial asking price of $1500 felt steep considering the bike’s condition. After some negotiation, I managed to bring the price down to $1300, and the project officially began.

The 1992 Honda Nighthawk 750 acquired for the Daryl bike project

The 1992 Honda Nighthawk 750 acquired for the Daryl bike project

Transporting the Nighthawk home was straightforward. Unloading and parking it in the garage marked the real start of the adventure. The next morning, before diving into carburetor cleaning, a hunch led me to try starting it one more time. Playing with the choke and starter for about 15 seconds, the engine roared to life. After a warm-up and a short ride, including a highway stretch to clear out any remaining issues, the Nighthawk was running surprisingly well. A lucky break and a testament to the resilience of these Honda engines!

Securing the Exhaust System

My initial preference was to find a Nighthawk with its stock exhaust. However, those available either had high mileage or inflated prices exceeding $2000. eBay became the next hunting ground for the elusive stock exhaust. I tracked an auction ending around the time I was inspecting the Nighthawk. Priced at $150 with free shipping, it seemed like a steal, especially considering the size of the part. It had been relisted, suggesting low demand. Not wanting to bid prematurely without securing the bike, I took a gamble. Unfortunately, I missed the auction’s end by minutes. It closed unsold, but frustratingly, the seller claimed it was sold and became uncooperative. Despite this setback, fortune favored the project. Another stock exhaust surfaced, listed at $300 with free shipping. Though described as more damaged, the critical areas were intact, as the build requires exhaust modification. Crucially, it had a “Make Offer” option. Starting with a low offer of $100, we negotiated and settled at $150 with free shipping – another victory in sourcing parts affordably.

The Yamaha R6 Front End Transformation

The Yamaha R6 front end is a defining feature of Daryl’s bike, lending it a modern, aggressive stance. Researching this component led to the discovery that 2008-2014 YZF-R6 models with gold fork years were the target. eBay searches revealed options, but often incomplete sets missing wheels, calipers, or controls. Serendipitously, some listings originated from a local shop. An email inquiry with my parts list confirmed they had almost everything needed, except the calipers. For $1000, I secured the front wheel, brake discs, forks, trees, stem, and controls. The missing front axle and calipers were subsequently sourced on eBay for $20 and $100 respectively, completing the R6 front end assembly.

Exhaust Wrap and Handlebar Details

Decoding the smaller details added another layer to the build. The exhaust wrap color initially seemed ambiguous in reference photos, appearing sometimes titanium, sometimes tan. Ultimately, tan was chosen, and a 50′ roll of DEI 2″ exhaust wrap was ordered online for $30. While cheaper alternatives existed, the risk of quality issues with generic wraps led to opting for a reputable brand like DEI, common knowledge in bike forums for reliable exhaust wrap.

DEI tan exhaust wrap chosen for the Daryl bike project

DEI tan exhaust wrap chosen for the Daryl bike project

Handlebars were next. Classified Moto helpfully listed “SE CR Hi” handlebars on their build sheet. A quick search clarified this as “Seven Eighths diameter, CR Hi bend” by Pro Taper. eBay again provided options, but color became the next question: black or titanium? Visual analysis, especially a specific reference shot, leaned towards titanium, confirmed by community consensus. These Pro Taper bars were sourced for $63.

Seeking Community Expertise for Detail Parts

With the major components secured, the project entered a temporary holding pattern awaiting parts deliveries. The focus shifted to identifying smaller, detail-oriented parts, leveraging the collective knowledge of online communities like The RPF.

First, the perforated metal used on the exhaust and fork cover plate needed clarification. The exhaust end diameter is roughly 4″, and the guess was 1/8″ holes in stainless steel.

Close-up of perforated metal detail on the Daryl bike's exhaust

Close-up of perforated metal detail on the Daryl bike's exhaust

Perforated metal detail on the fork cover plate of Daryl's motorcycle

Perforated metal detail on the fork cover plate of Daryl's motorcycle

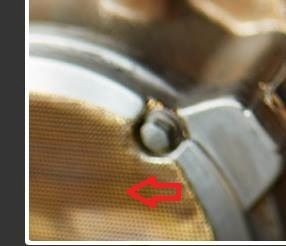

Next, the mesh size and material were queried. Contacting Classified Moto directly, a friend learned it was brass mesh they had in their shop, possibly fuel-related brass mesh. It appears in two locations: the exhaust and the crankcase cover.

Brass mesh detail on the exhaust of Daryl's bike

Brass mesh detail on the exhaust of Daryl's bike

Brass mesh detail on the crankcase cover of Daryl's motorcycle

Brass mesh detail on the crankcase cover of Daryl's motorcycle

Finally, identification of the brake light, headlight, mirror, and kick starter remained. Attempts to contact Classified Moto directly were unsuccessful, likely due to their busy schedule. Interest in acquiring the custom seat, bag, and upper tree from Classified Moto also lingered.

This marks the current stage of the Daryl bike replica project. More updates will follow as parts arrive and the build progresses. The journey of recreating Daryl Dixon’s iconic motorcycle is underway, piece by piece.