The drivetrain is what makes your bike move when you pedal, allowing you to conquer varying terrains by changing gears to adjust riding effort.

In simple terms, the drivetrain is the system of parts responsible for propelling your bicycle forward.

This article will delve into the various bike components that constitute a drivetrain, explaining their roles and how they work together. We aim to provide a comprehensive understanding of this essential system for both novice and experienced cyclists.

What Exactly is a Bike Drivetrain?

Shimano 105 Di2 R7100 road groupset

Shimano 105 Di2 R7100 road groupset

Within the broader context of a bike’s groupset, the drivetrain is a key subsystem. The groupset encompasses all the components that enable you to move and stop, including shifters and brakes in addition to the drivetrain.

While shifters are not technically part of the drivetrain itself, they are the control interface. Shifters are the components that allow you to manipulate the drivetrain when you decide to change gears for different riding conditions.

Key Components of a Bike Drivetrain

Campagnolo Ekar GT rear derailleur, chain and cassette

Campagnolo Ekar GT rear derailleur, chain and cassette

A typical bike drivetrain is composed of several interconnected components that function in harmony to provide gear changes and propulsion.

Most drivetrains include one or two derailleurs, which are mechanisms that shift the chain between different gears when activated by the shifters.

The chain is a crucial element, linking all parts of the drivetrain. It runs through the derailleurs, over the cassette (rear gears), and the crankset (front gears), allowing you to transfer pedaling force through the system to move the bike.

It’s important to note that not all bicycles are equipped with gears. For instance, singlespeed bikes simplify the drivetrain by using only one gear ratio. Additionally, some bikes utilize alternative drive systems like belt drives, which offer different characteristics compared to chain-based drivetrains.

Exploring 1x and 2x Drivetrain Configurations

Campagnolo Ekar chainring on Niner RLT 9 RDO

Campagnolo Ekar chainring on Niner RLT 9 RDO

A notable trend in modern cycling, particularly in gravel bikes and mountain bikes, is the increasing adoption of 1x drivetrains over traditional 2x drivetrains, which are still common on road bikes.

The distinction lies in the chainrings and front derailleur setup. A 2x drivetrain incorporates two chainrings at the front and a front derailleur to shift between them, while a 1x drivetrain simplifies the system with a single chainring and no front derailleur.

Choosing a 1x drivetrain offers several advantages, including weight reduction due to fewer components and eliminating the need for a front derailleur cable or electronic wire.

To prevent chain drops in the absence of a front derailleur, 1x chainrings often feature a ‘narrow-wide’ tooth profile. This design alternates between narrow and wide teeth to improve chain retention.

Furthermore, rear derailleurs on 1x systems frequently include a clutch mechanism. Although adding a bit of weight, this clutch enhances chain stability and reduces chain slap, especially beneficial for off-road riding.

Crankset: The Heart of the Drivetrain

Shimano Ultegra R8100 Di2 groupset – 52/36t crankset

Shimano Ultegra R8100 Di2 groupset – 52/36t crankset

The crankset, also known as the chainset or cranks, is arguably the most visually prominent component of the drivetrain.

Its primary function is to initiate chain movement as you pedal. It efficiently transfers the force from your legs to the drivetrain and subsequently to the rear wheel, propelling you forward.

Cranksets are built with two crank arms and one or more chainrings. The chain engages with these chainrings as it rotates.

Bottom bracket bearings are essential for smooth and free crankset rotation.

Most cranksets include an integrated axle or spindle for structural integrity. However, some older designs might have a separate axle as part of the bottom bracket assembly.

Chainrings: Your Front Gears

Verve aero chainring

Verve aero chainring

Chainrings act as your front gears, featuring teeth that interlock with the chain to drive it.

Bikes typically come with one, two, or even three chainrings, depending on their intended use and gear range requirements.

When selecting chainrings, consider the range of gears needed in conjunction with your cassette to match your typical riding terrain and style.

Chainrings are available in various sizes, denoted by the number of teeth. For example, a “50-34” crankset has a larger 50-tooth outer chainring and a smaller 34-tooth inner chainring. For 1x setups, you’ll see a single number like “40t,” indicating a single 40-tooth chainring.

Cranks: Leverage for Pedaling

Quarq DUB carbon crank

Quarq DUB carbon crank

The crankset includes two crank arms. Pedals are attached to these arms via threaded sections at the ends.

Cranks come in different lengths, usually ranging from 165mm to 175mm. Longer cranks provide increased leverage, which can be beneficial for power transfer.

Crank length is often specified based on bike size and rider height. However, individual leg length variations can influence optimal crank length for performance and comfort, making it a worthwhile area for cyclists to explore for personalized bike fit.

Front Derailleur: Shifting Between Front Chainrings

Shimano 105 Di2 front derailleur on a Dolan ADX

Shimano 105 Di2 front derailleur on a Dolan ADX

The front derailleur is responsible for moving the chain between the different chainrings on the crankset. As the name implies, it ‘derails’ the chain from one chainring and guides it onto another.

The front derailleur is typically controlled by the left-hand shifter on most standard shifting systems. Electronic groupsets offer customization, allowing you to assign shifting functions to different buttons through dedicated apps.

Bikes with a single chainring drivetrain do not require a front derailleur. This is a common design choice for mountain bike gears and gravel bikes to simplify operation and reduce weight.

Front derailleurs are mounted to the bike frame in two primary ways: band-on and braze-on.

Band-on derailleurs use a clamp that wraps around the seat tube of the frame for mounting.

Braze-on front derailleurs attach to a dedicated mounting plate, typically riveted to the seat tube.

For compatibility, it’s generally recommended to use a front derailleur from the same manufacturer and series as the rest of your groupset to ensure seamless integration.

Rear Derailleur: Managing Rear Gear Changes

Thok TK01 R enduro electric mountain bike

Thok TK01 R enduro electric mountain bike

The rear derailleur is the component that shifts the chain across the cassette sprockets at the rear wheel, enabling you to change rear gears.

While rear derailleurs come in various types and designs, their fundamental function and operation remain consistent.

The rear derailleur is actuated by the right-hand shifter in most groupset systems.

It includes a derailleur cage that holds pulley wheels (also known as jockey wheels). The chain wraps around these pulleys, facilitating gear changes.

Rear derailleurs are designed for a specific number of ‘speeds’ or gears, ranging from 7-speed up to 13-speed systems.

Some rear derailleurs incorporate chain retention features, such as a clutch mechanism, to minimize chain slap against the chainstay, especially beneficial for rough terrain and quieter riding.

Rear derailleurs typically attach to the bike frame via a replaceable derailleur hanger using a single bolt, designed to break in case of impact to protect the frame and derailleur.

Similar to front derailleurs, maintaining consistency with the manufacturer and groupset series for your rear derailleur is crucial. This is because shifter cable pull ratios (the amount of derailleur movement per unit of cable pulled) are specifically matched between shifters and rear derailleurs.

Cassette: Rear Gears for Varied Terrain

SRAM Rival XPLR eTap AXS cassette and rear derailleur

SRAM Rival XPLR eTap AXS cassette and rear derailleur

The cassette is a cluster of sprockets (cogs) mounted on the rear wheel’s freehub body. It’s a replaceable part that provides your bike’s rear gears. The rear derailleur moves the chain across these sprockets to change gears.

Cassettes are available in a wide range of gear ratios to suit different cycling disciplines and rider preferences. Cassette size is typically described by its smallest and largest cog sizes. For example, an “11-32” cassette has an 11-tooth smallest cog and a 32-tooth largest cog.

Gravel and mountain bikes commonly use cassettes with a wider gear range compared to road bikes. This wider range is essential for 1x drivetrains, providing easier gears for climbing steep inclines and higher gears for speed on flats and descents.

Cassettes can have anywhere from 7 to 13 sprockets, depending on the intended use and the groupset’s design. Current top-tier road bike groupsets and mountain bike groupsets from Shimano and SRAM often feature 12-speed cassettes. Campagnolo also utilizes 12-speed for road, but their Ekar gravel groupset and Ekar GT offer 13-speed options.

The cassette mounts onto the freehub, a component of the rear wheel hub. Cassettes have internal notches that align with splines on the freehub body.

Different manufacturers and brands use various spline designs. It’s critical to ensure compatibility between your cassette and freehub, particularly when upgrading wheels or cassettes. Our guide to freehubs offers detailed information on freehub types, function, and compatibility.

Chain: The Drivetrain Workhorse

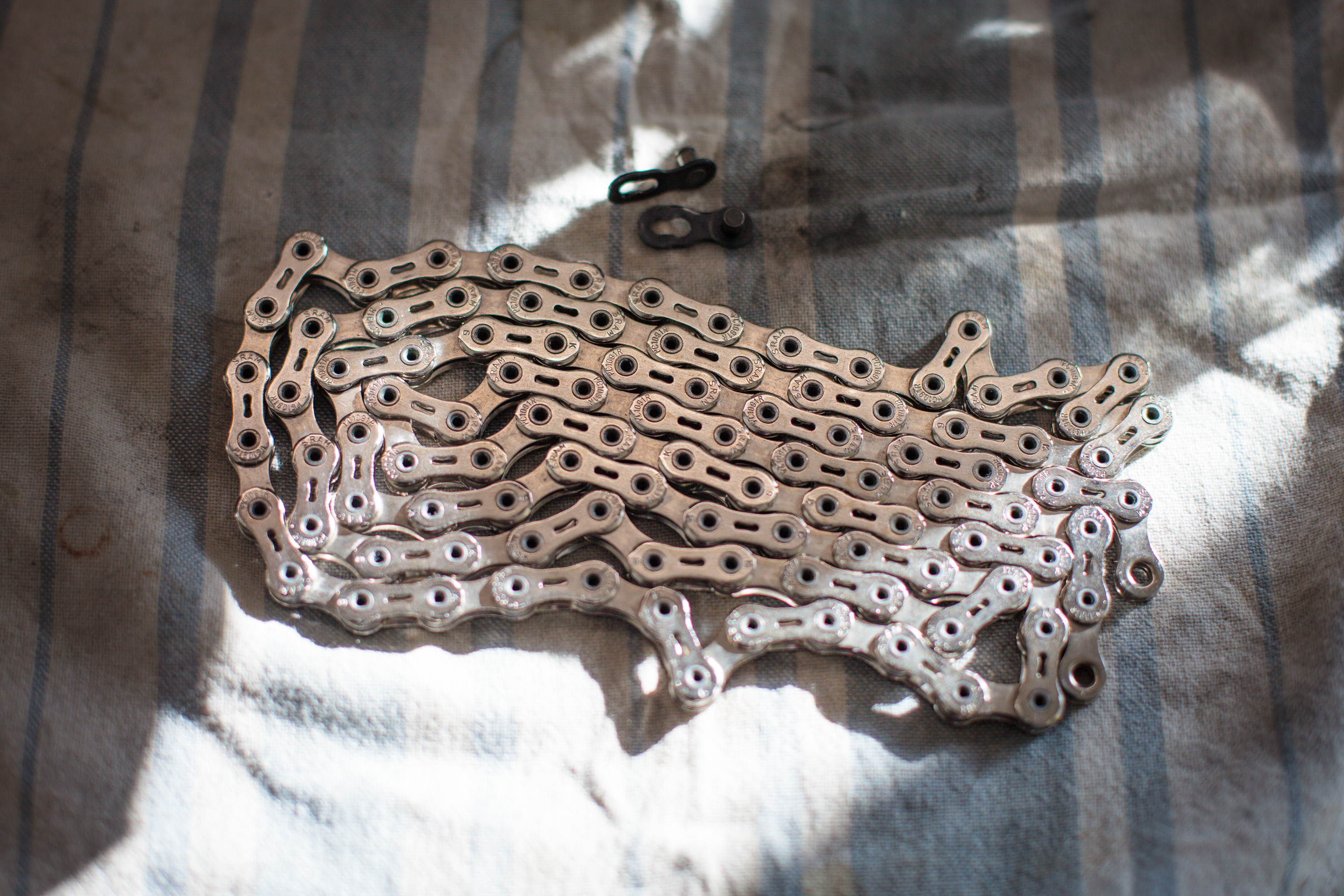

Clean bicycle chain ready for waxing

Clean bicycle chain ready for waxing

The chain is the drivetrain component that endures the most stress and wear as it interacts with all other parts.

A bike chain is constructed from numerous links, typically alternating between wide and narrow links in a repeating pattern along its length.

Chains are also designed for a specific number of ‘speeds,’ and it’s essential to use a chain compatible with your groupset’s speed. Always verify compatibility when replacing your chain.

Chains wear out over time due to use. They elongate (stretch), and the side-to-side play between links increases. Chains are often the first drivetrain component requiring replacement.

If a worn chain is not replaced promptly, it can accelerate wear on the cassette and chainrings, which are more expensive to replace. Regularly checking your chain wear and replacing it when needed is a proactive maintenance step. Learn how to know when it’s time to replace your bicycle chain.

We offer a detailed guide on how to replace your chain to help you with this essential maintenance task.

Electric Bike Drivetrains: Motor Integration

2022 Whyte E-160 RSX 29er electric mountain bike

2022 Whyte E-160 RSX 29er electric mountain bike

Electric bike drivetrains can differ from traditional drivetrains depending on the type of electric motor used.

Electric bikes with hub-based motors generally utilize conventional, geared drivetrains.

However, e-bikes equipped with bottom-bracket motors, commonly found on the best electric bikes, often have design constraints that make front derailleurs incompatible. As a result, these bikes typically employ 1x drivetrains. There are, however, some exceptions where front derailleurs are integrated.

Singlespeed and Fixed-Gear Drivetrains: Simplicity and Efficiency

Halo track hubs

Halo track hubs

Singlespeed and fixie bikes feature significantly simpler drivetrains compared to geared bikes. They eliminate derailleurs, cassettes, and shifters.

These drivetrains typically consist of a wider, more robust chain, chainring, and sprocket. They are known for their efficiency because the chain runs in a straight line, avoiding the angles introduced by derailleurs, which can increase wear and friction.

Choosing the correct chainring and sprocket size for a singlespeed bike is crucial and depends heavily on the intended riding terrain.

Some singlespeed bikes include [freehubs], allowing you to coast, while fixed-gear bikes do not, requiring continuous pedaling.

Hub Gears: Internal Gear Systems

Raleigh Motus Tour commuter eBike

Raleigh Motus Tour commuter eBike

Hub gears present another drivetrain alternative, commonly found on commuter bikes.

Instead of external derailleurs, hub gear systems integrate the gears within the rear wheel hub. This design reduces maintenance needs but comes with trade-offs. Hub gears are generally heavier than derailleur systems, and maintenance can be more complex when required.

Belt-Drive Systems: Clean and Durable Alternative

The Canyon Commuter 7 is equipped with a Gates Carbon CDN belt drive

The Canyon Commuter 7 is equipped with a Gates Carbon CDN belt drive

Some bicycles utilize a belt drive instead of a chain. Belt drives are particularly favored for commuter bikes because they are cleaner, minimizing the risk of grease stains on clothing. They are also increasingly used on electric bikes.

Belt-drive systems replace the cassette and chainrings with a belt and corresponding pulleys. They offer lower maintenance as they are made from non-metallic materials and do not require lubrication or degreasing.

Typically, belt drives operate more quietly and are more durable than chain drivetrains. However, they can be less efficient in power transfer, generally more expensive, and replacement parts can be less readily available.