The past year has witnessed a significant surge in the conversion of motorcycles to electric powertrains. A closer look at the components favored in these transformations reveals the popularity of Quan Shun (QS) cylindrical motors. This trend prompts an exploration into the factors driving the adoption of Electric Motor Bike Motors, particularly QS motors, in motorcycle conversions.

The Advantage of Twin Spar Frames for Electric Conversions

A key factor contributing to the current wave of electric drive conversions for dirt bikes is the availability of affordable used models. Many of these bikes are reaching an age where their combustion engines are worn and require costly rebuilds, making them prime candidates for electric swaps.

Interestingly, a design evolution in motorcycle frames from a decade or two ago has inadvertently paved the way for easier electric conversions. The shift from a single backbone top tube to a “twin spar” frame design has proven particularly beneficial. This design change simplifies the integration of large, single-piece battery packs, a crucial element in electric motorcycle conversions.

Previously, custom battery solutions often resulted in awkwardly shaped packs or assemblies of multiple connected sections, as seen in some earlier projects. These configurations invariably compromised battery capacity compared to what the frame could theoretically accommodate.

Honda CR250 frame comparison highlighting twin-spar design for electric motor bike motor conversion

Honda CR250 frame comparison highlighting twin-spar design for electric motor bike motor conversion

Caption: A comparative view of a 2009 Honda CR250 aluminum frame with a traditional top bar (left) and a newer 2010 twin-spar design (right). Both frames feature a vertically mounted long-stroke shock absorber behind the engine bay.

This consideration is significant because electric dirt bike conversions inherently face range limitations, even under optimal conditions. The battery pack’s shape and size are paramount. The Husqvarna conversion by Jeremy Webb showcased a battery design that truly impressed with its monolithic block shape, maximizing space utilization within a twin-spar frame. Initially, such frames might have seemed scarce, but widespread adoption of the twin-spar design by major manufacturers has made them readily accessible for conversions.

Jeremy Webbs Husqvarna 250 conversion showcasing battery pack integration with electric motor bike motor

Jeremy Webbs Husqvarna 250 conversion showcasing battery pack integration with electric motor bike motor

Caption: Jeremy Webb’s Husqvarna 250 electric conversion. The battery pack’s tall, monolithic shape is a key feature, demonstrating efficient use of space in an electric motor bike motor conversion.

QS Motors: A Popular Choice for Electric Motorbike Conversions

Quan Shun (QS) motors first gained attention in the electric vehicle community with their large hub motors, introduced in 2015. Their most recognized model features a 205mm diameter and 50mm wide stator (205/50H in Chinese motor nomenclature, where “H” denotes magnet height). While officially rated at 3000W continuous power, enthusiasts have pushed these motors to temporary peak power levels of 7200W (72V / 100A) in hot-rod applications.

Quan Shun 3000W hub motor for electric conversions

Quan Shun 3000W hub motor for electric conversions

Caption: A 3000W Quan Shun hub motor designed for scooter conversions, demonstrating the range of electric motor bike motor solutions available.

The image above illustrates a QS hub motor designed for scooter conversions, directly mounting to 10-inch scooter tires. China’s efforts to combat urban pollution have spurred a surge in electric vehicle conversions as a sustainable alternative to replacing existing vehicles. QS Motors offers a comprehensive web-catalog showcasing their mid-drive motor options suitable for various electric motor bike motor projects.

Why are QS Motors Favored in Electric Motor Bike Motor Conversions?

A recurring question among enthusiasts is, “Which frame is ideal for conversion?” or “What motor and controller suit my brand-X frame?”. While experience with electric bicycles is extensive, hands-on experience with electric motorcycles can be less common.

Traditionally, recommending turnkey electric motorcycles was the go-to advice. For younger riders, Kuberg models are well-regarded. The Sur-Ron has gained significant popularity for mid-sized adult dirt bikes. For full-sized off-road capabilities, Zero Motorcycles’ FX model stands out.

Kuberg Freerider electric bike motor for youth riders

Kuberg Freerider electric bike motor for youth riders

Caption: The 48V Kuberg Freerider, utilizing mountain bicycle components and lightweight design, caters to younger riders with options for 20-inch or 24-inch MTB bicycle wheels, showcasing a smaller scale electric motor bike motor application.

Sur-Ron electric bike motor with motorcycle-grade components

Sur-Ron electric bike motor with motorcycle-grade components

Caption: The 60V Sur-Ron, a popular choice in electric motor bike motor conversions, features motorcycle-grade components and is supported by US distributor Luna Cycle for upgrades and customization.

Zero FX full-sized off-road electric motor bike

Zero FX full-sized off-road electric motor bike

Caption: The Zero FX, a full-sized 293-lb off-road electric motorcycle, offers high performance with a 102V powertrain and approximately 100 miles of range, representing a high-end electric motor bike motor solution.

Previously, recommending specific frames or conversion kits was avoided due to limited component choices and a lack of user-reported data. It was crucial to avoid endorsing products prematurely without evidence of customer satisfaction.

However, recent data collection on motorcycle conversions reveals a trend: QS cylindrical motors are increasingly prevalent and garnering positive feedback from builders.

A general guideline is to utilize the largest motor that fits within the frame. For smaller dirt bike conversions, the QS 3000W (3kW) 138/70H V3 motor, equipped with a 45T/19T gear reduction (2.3:1 ratio), emerges as a sweet spot.

QS 3000W 138/70H V3 electric motor bike motor

QS 3000W 138/70H V3 electric motor bike motor

Caption: The QS 3000W 138/70H V3 motor, a popular choice for electric motor bike motor conversions, offering a balance of power and size.

This 3kW motor (138/70H) is also available without gear reduction, featuring a standard splined shaft. For enhanced torque, the 138/90H motor, rated at 4kW continuous, is an option, although currently lacking a gear reduction variant.

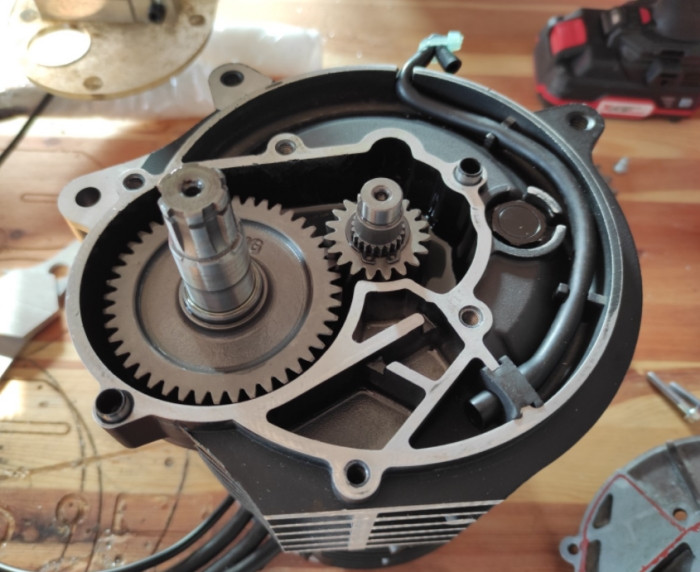

QS 138/70H gear reduction for electric motor bike motor

QS 138/70H gear reduction for electric motor bike motor

Caption: The 2.3:1 gear reduction system integrated into the QS 138/70H electric motor bike motor, enhancing torque output.

Helical gears in QS 138/70H motor for quieter operation

Helical gears in QS 138/70H motor for quieter operation

Caption: Close-up view of the helical gears within the QS 138/70H electric motor bike motor’s reduction system, designed for quieter performance compared to spur gears.

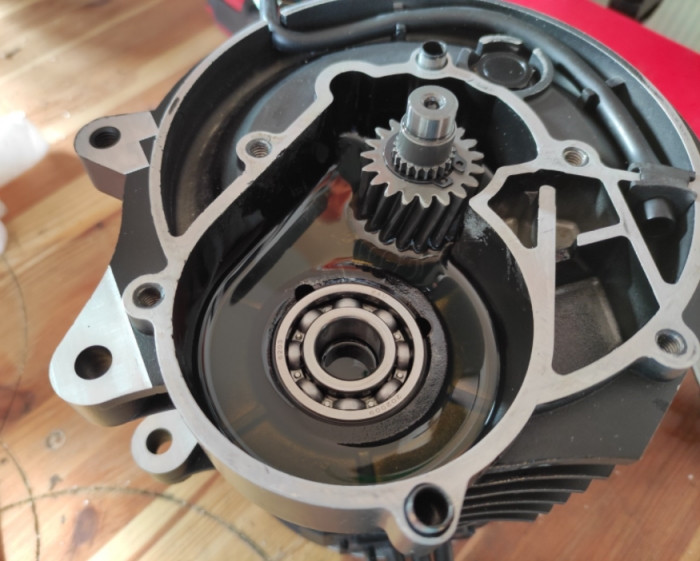

Removable end-cap with robust bearings in QS motor

Removable end-cap with robust bearings in QS motor

Caption: The removable end-cap of a QS electric motor bike motor, showcasing robust bearings for durability and reliability.

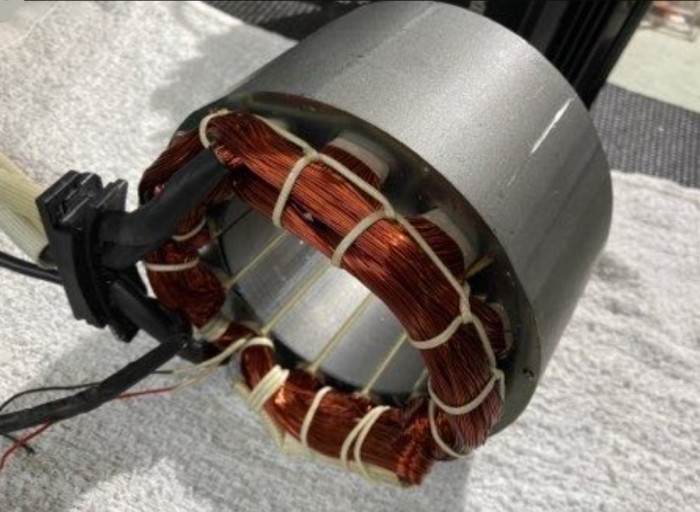

QS 138/70H stator without rotor or cover plates

QS 138/70H stator without rotor or cover plates

Caption: The stator of the QS 138/70H electric motor bike motor, exposed without the rotor or finned cover plates, revealing its internal construction.

QS 138/70H rotor component

QS 138/70H rotor component

Caption: The rotor of the QS 138/70H electric motor bike motor, a key component in generating rotational force.

Magnet shape and placement in QS 138/70H rotor

Magnet shape and placement in QS 138/70H rotor

Caption: A detailed view of the magnet shape and placement within the QS 138/70H rotor, highlighting the design for efficient electric motor bike motor performance.

Tesla Model-3 Interior Permanent Magnet layout comparison

Tesla Model-3 Interior Permanent Magnet layout comparison

Caption: Comparison of the QS 138/70H rotor’s magnet layout with the “Interior Permanent Magnet” (IPM) design of the Tesla Model-3 motor, showcasing similarities in advanced electric motor bike motor technology. Image courtesy of Munroe & Associates.

Suzuki RM-Z450 with QS 138/90H electric motor bike motor

Suzuki RM-Z450 with QS 138/90H electric motor bike motor

Caption: A 2018 Suzuki RM-Z450 motorcycle converted with a QS 138/90H electric motor bike motor, demonstrating a successful high-power conversion.

According to the builder of the Suzuki RM-Z450 conversion: “…It’s the first time I rode an electric bike and I am hooked! It so much fun…It hits very hard, maybe I will need to de-tune it a bit…weight is 255 lbs, but it feels way lighter than that when moving. Feels lighter than my KTM….I have a lot of tuning to do, but as of now it feels like a 125 but with lots more torque down low…“

4000W 138/90H electric motor bike motor with DIY chain reduction

4000W 138/90H electric motor bike motor with DIY chain reduction

Caption: The 4000W 138/90H electric motor bike motor featuring a DIY chain reduction system on the right side, driving a jackshaft to the final-drive sprocket, illustrating custom adaptation in electric motor bike motor installations.

QS 3000W 138/70H motor mounted on KTM 200 EXC

QS 3000W 138/70H motor mounted on KTM 200 EXC

Caption: A QS 3000W 138/70H electric motor bike motor, without gear reduction, mounted on a KTM 200 EXC motorcycle using a 12T sprocket, showing a direct drive configuration.

The 138/90H motor measures 217mm in length and 162mm in diameter (approximately 8.5 inches long by 6.4 inches), with the shaft extending an additional 14mm (1.4 inches). While larger motors are available in the QS catalog, such as the 8,000W 171/100H, the 138/90H size is already substantial for most dirt bike frames. The 171/100H is roughly 33mm larger in diameter and 10mm longer than the 138/90H.

Controllers for QS Electric Motor Bike Motors

QS Motors offers their 138/70H and 138/90H motors with controller options from APT, Kelly, Sabvoton, or their partner Votol. Votol controllers are frequently chosen due to their affordability and compatibility with the 138-series motors. The EM-150 and EM-200 models are particularly well-suited for these motors.

The Votol controller model numbers (EM-150, EM-200) indicate continuous current amperage. The EM-200 can reportedly handle temporary peaks of 250A. The EM-150 pairs effectively with the 138/70H motor, while the EM-200 is a suitable match for the 138/90H, although some builders use the EM-200 even with the 138/70H for increased headroom.

Votol EM-200 and EM-150 controllers for electric motor bike motors

Votol EM-200 and EM-150 controllers for electric motor bike motors

Caption: A size comparison of the Votol EM-200 controller (left) and the EM-150 controller (right), both designed for electric motor bike motor applications.

Votol EM-200 and EM-150 controllers for electric motor bike motors

Votol EM-200 and EM-150 controllers for electric motor bike motors

Caption: The Votol EM-200 controller, featuring 24 MOSFETs and a baseplate of 285mm X 168mm, designed for high-performance electric motor bike motor systems. Image courtesy of Silent Enduro in Ukraine.

The EM-200 controller utilizes 24 MOSFETs, rated at 8.4 continuous amps per FET. It has dimensions of 285mm x 168mm with a 70mm thickness. Capacitor voltage is capped at 90V, providing a 6V safety margin for voltage spikes when used with a 72V (20S) battery (84V fully charged).

Votol’s product range extends to smaller controllers like the EM-30, EM-50, and EM-100, and even larger models such as the EM-300, catering to diverse electric motor bike motor power requirements.

While Votol is common, QS motors can also be paired with other controllers, such as the Kelly QS-KLS-8430H, as demonstrated in some builds.

Electro-Braap: A Resource for Electric Motor Bike Motor Conversion Kits

Research into QS motors and dirt bike conversions often leads to “Electro and Company,” known online as “Electro-Braap.” Based in Oakley, California, Electro-Braap provides swap kits and support for electric motorcycle conversions. Their Facebook page and website offer valuable information and resources.

Electro Braap confirms stock of 10T and 11T sprockets for #428 chain, compatible with the motors they sell. Responding to customer demand, they have also stocked #520 sprockets. For the 90H motor’s external jackshafts, builders commonly utilize readily available industrial components from suppliers like McMaster-Carr.

The Performance and Appeal of Electric Motor Bike Motors

Whether opting for a turnkey electric dirt bike or a DIY conversion, electric motorcycles have experienced a surge in popularity. Their quiet operation allows riding in more locations, and their instant low-end torque is a significant performance advantage. Kilowatt/horsepower ratings can be misleading for electric motors; wheel torque is the more relevant performance metric.

Electric motorcycles excel in wheel torque, a key differentiator noted by experienced riders. Unlike combustion engines, electric motors deliver full torque from zero RPM, eliminating the need for clutches and gear shifting. Furthermore, electric motors offer benefits like reduced noise, and less frequent maintenance compared to gasoline engines.

To appreciate the capabilities, consider a Kawasaki KX350 conversion with a QS 138/70H motor, showcasing impressive performance.

Sur-Ron riders often describe the bike as having the agility of a 125cc dirt bike with the torque of a 250cc. Listed horsepower figures for electric motorcycles may be technically understated; therefore, wheel torque provides a more accurate performance comparison against gasoline counterparts.

Performance Limits and Potential of Electric Motor Bike Motors

A kart conversion video highlights the QS 138/70H motor’s potential. Running at 96V with 250A peak current, this kart demonstrates impressive power. Brushless motors are voltage-tolerant, with voltage increases primarily limited by battery cell availability and controller voltage limits. High amperage setups, especially with controllers like the Votol EM-200, require careful thermal management to prevent motor overheating, potentially necessitating a motor heat sensor.

At 96V and 250A, the kart operates at 24,000W (24kW), a substantial power level. However, as explained by a Zero Motorcycles engineer, rapid acceleration means peak amperage draw is typically brief.

This kart utilizes a DIY battery pack with 26 BMW hybrid cells salvaged from a car wreck (26S configuration). Hybrid vehicle battery cells are optimized for high amperage discharge, unlike full EV cells focused on range. The pack’s 96V nominal voltage reaches 107V at full charge (4.1V/cell), nearing the Votol controller’s voltage limit.

Another conversion video showcasing a QS 138 motor running at 117V reports performance comparable to a 450cc motorcycle, further illustrating the performance potential of these electric motor bike motors.

Useful Resources for Electric Motor Bike Motor Conversions

- QS Motor Website

- Votol Controller Website

- Electro Braap Facebook Page

- Electro & Company Website

- Zero Motorcycles Developer Kit

- Electro Braap YouTube Channel (80 E-conversion videos)

Written by Ron/spinningmagnets, April 2021