Global Bike Inc. (GBI) serves as a compelling case study, illustrating the intricacies of a global business within the bicycle industry. While GBI is a fictional entity created for educational purposes by Epistemy Press, its structure, operations, and challenges mirror those faced by real-world global bike companies. This overview delves into GBI’s history, business processes, product lines, customer base, and vendor relationships, providing a comprehensive look at a representative “Global Bikes” enterprise.

Company Origins: From Racing Champions to Business Partners

GBI’s foundation is rooted in the merger of two distinct yet complementary companies. John Davis, a celebrated mountain bike racing champion from the United States, established a company specializing in trail bike production. Simultaneously, in Germany, Peter Weiss, an engineer and road bike racing enthusiast, founded a company focused on designing and manufacturing lightweight touring bike frames. In 2000, recognizing synergistic opportunities, Davis and Weiss joined forces, creating Global Bike Inc. (GBI). This merger combined expertise in both mountain and road biking disciplines, setting the stage for GBI’s broad market appeal.

Business Focus: Serving the Professional and Prosumer Cycling Market

GBI strategically targets the professional and “prosumer” cyclist market, catering to enthusiasts who demand high performance and quality in both mountain and touring bikes. The company is particularly renowned for its carbon composite frames, a hallmark of their professional bike line. These frames are celebrated for their strength, lightweight design, and minimal maintenance requirements. In contrast, GBI’s deluxe bike line features aluminum frames, offering a balance of performance and affordability.

A prime example of GBI’s product excellence is the Professional Touring Bike in Black (PRTR1000). This model, showcased in Figure 2, embodies GBI’s commitment to quality with its carbon composite frame and typically retails for approximately 3,200 USD in the United States.

GBI Bike

GBI Bike

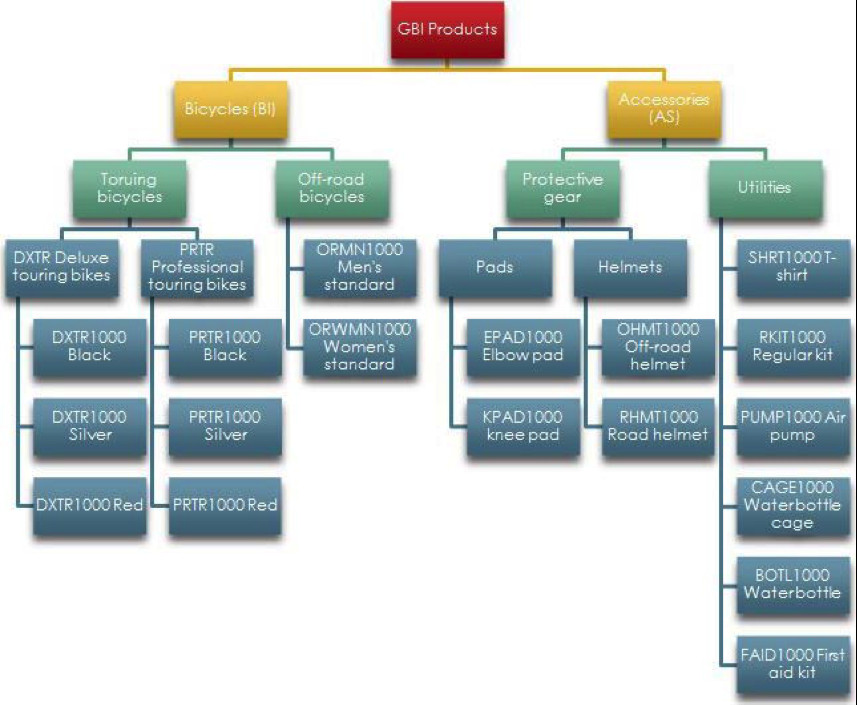

Beyond bicycles, GBI expands its market reach by offering a range of cycling accessories. Helmets, first aid kits, apparel like shirts, and water bottles represent some of the non-bike products GBI provides, enhancing the overall customer experience. Figure 3 provides a comprehensive list of GBI’s diverse product offerings.

GBI Producs

GBI Producs

Innovation, safety, reliability, and performance are the cornerstones of GBI’s business philosophy. This unwavering commitment to core values has enabled GBI to maintain a competitive edge in a dynamic market facing increasing competition and counterfeit products. GBI’s distribution strategy is unique; it does not sell directly to consumers. Instead, GBI partners with high-end retailers, emphasizing quality and specialized service.

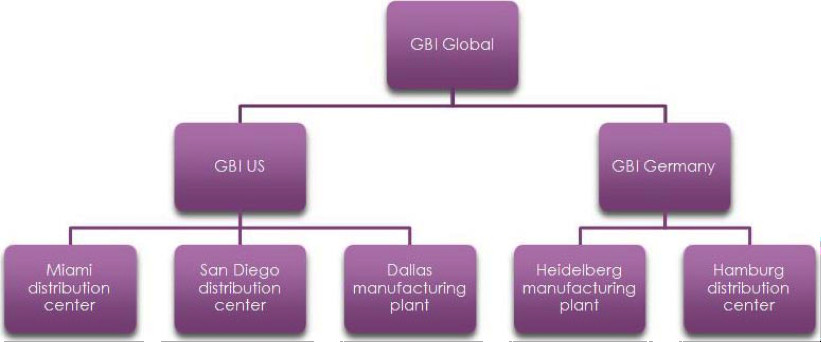

Organizational Structure: A Transatlantic Operation

GBI operates with a co-CEO leadership model, with founders John Davis and Peter Weiss sharing the helm. The company employs around 100 individuals, with approximately two-thirds based in the United States and the remainder in Germany, reflecting its transatlantic nature. Figure 4 illustrates GBI’s top-level organizational structure.

Figure 4: Top-Level Organizational Structure

Headquartered in Dallas, Texas (as depicted in Figure 5), GBI is officially registered as a U.S. company and adheres to U.S. Generally Accepted Accounting Principles (GAAP). GBI’s global footprint extends to Europe through its subsidiary, GBI Europe, located in Heidelberg, Germany. GBI Europe operates under International Financial Reporting Standards (IFRS) and complies with German tax regulations.

GBI Structure

GBI Structure

The Dallas headquarters centralizes crucial functions including materials planning, finance, administration, HR, and IT. The Dallas facility also serves as a manufacturing hub for the U.S. and export markets, and its warehouse manages distribution for the central U.S. and online retailers. GBI strategically utilizes warehouses in San Diego and Miami for broader distribution. San Diego facilitates West Coast distribution and exports to Asia, while Miami handles East Coast distribution and exports to Latin America.

GBI Europe’s Heidelberg location is the epicenter for research and development for the entire GBI organization. Heidelberg also serves as a primary European manufacturing facility. Distribution within Europe is managed through warehouses in Heidelberg (southern Europe) and Hamburg (United Kingdom, Ireland, Middle East, and Africa).

Business Partnerships: Customers and Vendors in the Global Bike Network

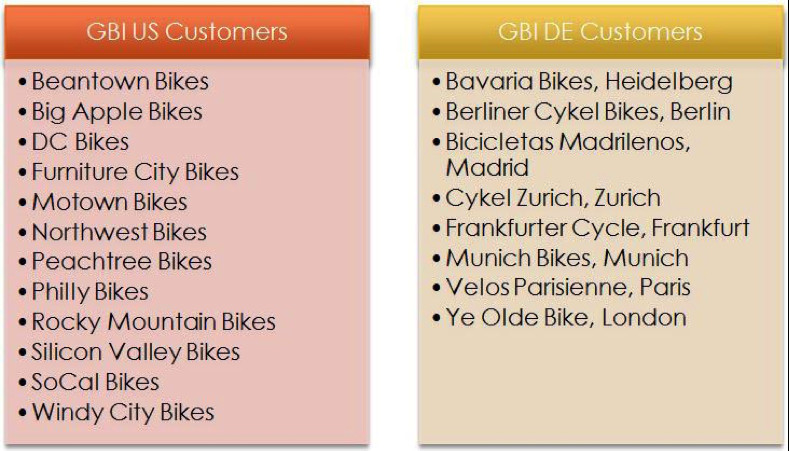

GBI’s go-to-market strategy relies heavily on Independent Bicycle Dealers (IBDs). These are carefully selected, reputable retailers with expert staff capable of guiding customers in choosing the ideal GBI bike and accessories. This partnership approach is crucial due to the specialized nature of GBI bikes and the personalized needs of cyclists. Figure 6 lists GBI’s key customers, highlighting the importance of these IBD relationships.

GBI Customers

GBI Customers

While recognizing the internet’s power for information dissemination and marketing to a global audience, GBI has strategically limited direct online sales. This decision is primarily driven by the complexities of tax regulations associated with selling products across numerous states and countries. Instead, GBI leverages its online presence to educate consumers and support its partner network.

GBI’s commitment to product reliability extends to its vendor relationships. The company partners with highly selective suppliers of raw materials and trading goods. These vendors are crucial to maintaining GBI’s high standards for quality and performance. Figure 7 provides a list of GBI’s vendors, emphasizing the importance of these supply chain partnerships.

GBI Vendors

GBI Vendors

Global Production and Distribution Network

GBI’s production operations are centered in two key facilities: Dallas and Heidelberg. Each plant operates three assembly lines, with each line capable of producing approximately 1,000 bikes annually. GBI’s total production capacity is around 6,000 bikes per year, with potential to increase output by 15%-20% through overtime and part-time labor. Significantly, GBI outsources the production of both off-road and touring frames, as well as carbon composite wheels, to specialized partners. This strategic outsourcing allows GBI to leverage the expertise of specialized manufacturers while maintaining close collaboration in research and design to ensure continuous innovation in materials and structural technologies.

GBI’s primary manufacturing focus at its Dallas and Heidelberg plants is the assembly of semi-finished goods into finished bicycles. Finished goods are then strategically stored in local warehouses or dispatched to regional distribution centers to efficiently fulfill customer orders across its global network.

Conclusion: A Model for Global Bike Business Operations

Global Bike Inc., while fictitious, provides a valuable framework for understanding the complexities and strategic considerations within the global bicycle industry. From its transatlantic organizational structure to its focus on high-quality products and strategic partnerships, GBI encapsulates the challenges and opportunities inherent in operating a “global bikes” business in today’s competitive market. GBI serves as a relevant model for studying business operations, supply chain management, and international business strategies within the context of a specialized product market.