Are you curious about how bike pedals are made? At usabikers.net, we’ll take you through the fascinating process of bike pedal manufacturing, from initial design to final testing, perfect for motorcycle and bicycle enthusiasts. Understanding the process helps bikers appreciate the craftsmanship and technology involved in creating reliable components. Discover the meticulous steps and advanced techniques that ensure quality and performance in every pedal, enhancing your riding experience.

1. Understanding the Bike Manufacturing Supply Chain

Bike manufacturing involves a complex supply chain, categorized by the level of processing done in-house versus outsourced. Understanding this chain helps appreciate the intricate steps in creating even a small component like a bike pedal. Let’s explore the different types of manufacturers involved.

1.1 What are Upstream and Downstream Processes in Bike Manufacturing?

Upstream and downstream refer to the specialization level in the manufacturing supply chain. The further upstream, the more specialized; downstream indicates a broader range of generic processing leading to final assembly. This division helps optimize production efficiency.

1.2 What are the 3 Main Types of Bike Manufacturers?

The three main types include close-to-the-source producers, elementary manufacturers, and comprehensive assemblers. Each type plays a unique role in the overall manufacturing process.

- Close-to-the-Source Producers: These firms handle raw materials, often doing most processing in-house.

- Elementary Manufacturers: They perform in-house processing and outsource some tasks, focusing on low-to-full assembly for less complex products.

- Comprehensive Manufacturers: These companies mainly assemble products, purchasing components and conducting limited in-house processing.

2. Exploring Pedal Manufacturing Stages

Pedal manufacturing involves distinct stages: design, CNC machining, assembly, and testing. Each stage is crucial to producing high-quality, durable pedals for bikes. Let’s delve into these stages.

2.1 What are the 4 Key Stages in Pedal Manufacturing?

The four key stages are design, CNC machining, assembly, and testing. These steps ensure precision and quality in every pedal produced.

- Design Stage: Creating CAD blueprints and selecting components.

- CNC Machining Stage: Converting designs into CNC G-code for component processing.

- Assembly Stage: Combining self-processed and sourced components into complete pedal sets.

- Testing Stage: Evaluating prototypes and batch samples against industry standards.

3. The Importance of the Design Stage

The design stage is where bike pedals come to life, starting from sketches to detailed CAD models. This phase sets the foundation for the entire manufacturing process. It’s an important process that can’t be skipped.

3.1 How Does the Pedal Design Stage Begin?

The pedal design stage often starts with rough sketches that are formalized into CAD models. This model serves as a blueprint for CNC machining.

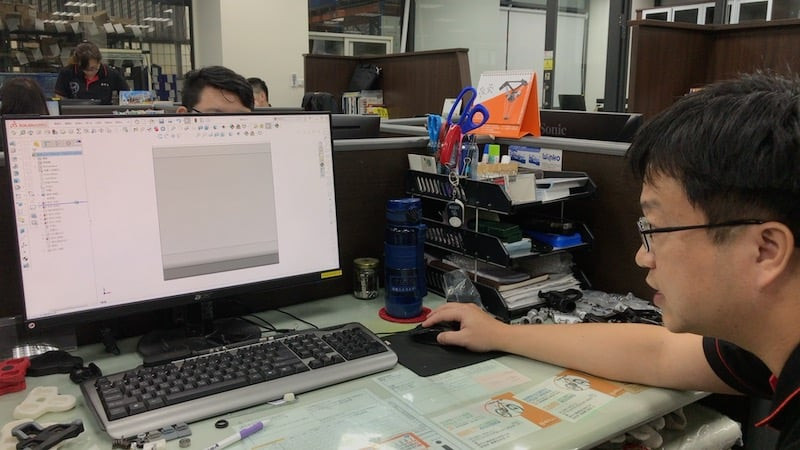

3.2 What is the Role of CAD in Pedal Design?

CAD (Computer-Aided Design) is more than just a blueprint; it forms the basis for the CNC machine’s program. The CAD model guides the cutting of the main form and etching of details.

Blank Flat Pedal Design

Blank Flat Pedal Design

Alt: CAD drawing of a blank flat bike pedal body, ready for CNC machining.

3.3 Can you break down the development process of the flat pedal?

We start with a blank pedal body scaled to the final dimensions in CAD. The CNC program uses these CAD instructions to cut the alloy precisely.

3.4 What Considerations Impact the Final Pedal Design?

Cost is a significant factor. Materials like nylon allow for basic designs, while CNC-machined alloy enables complex, durable pedals.

4. Unveiling the CNC Machining Stage

CNC (Computer Numerical Control) machining is a cornerstone of bike component manufacturing, offering customization and precision. It’s an incredible process.

4.1 Why is CNC Machining Important in Pedal Manufacturing?

CNC machining allows for the creation of almost any design imaginable from CAD. It’s used to manufacture pedals from die-cast aluminum or molded nylon with exacting tolerances.

4.2 What Expertise is Needed to Operate CNC Machines?

Operating CNC machines requires expertise and experience. Operators monitor machines, inspect samples, and adjust processes to ensure machining stays within prescribed tolerances.

4.3 How Does CNC Machining Work?

CNC machining typically processes one piece at a time or serially across multiple components. Machines use X, Y, and Z axes to move cutter heads and create precise shapes.

CNC Milling Machine Control Panel

CNC Milling Machine Control Panel

Alt: Control panel of a CNC milling machine displaying operational data and axis coordinates for precise cutting.

4.4 What are the Forms of CNC Processing?

CNC processing can be basic or complex, depending on the component. Complex processing involves intricate cutting routines, while basic processing might involve simple drilling.

4.4.1 What is Complex CNC Processing?

Complex processing involves using high-end CNC machines for precision cutting routines on specialized components. SCADA excels in this type of processing.

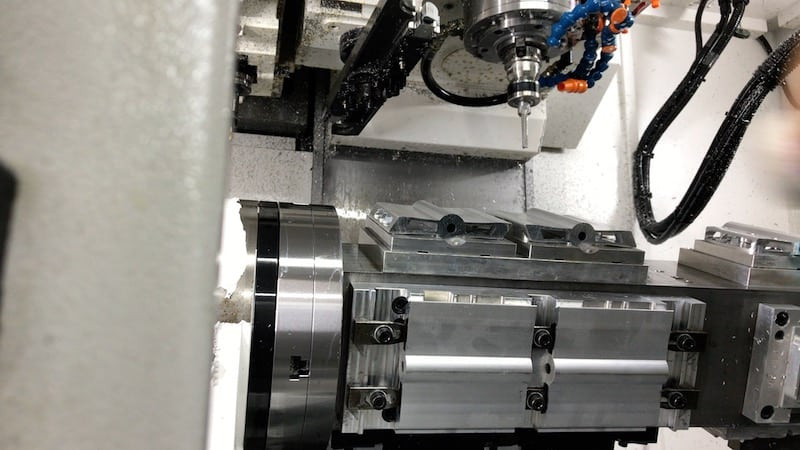

4.4.2 How is Complex CNC Processing Used in Pedal Manufacturing?

Pedals are bolted to a plate in pairs, and multiple plates are fixed in position. The cutter moves across the plates, processing a batch of pedals in one go, saving time and ensuring precision.

Close up of pedals on the CNC plate

Close up of pedals on the CNC plate

Alt: A close-up of bike pedals secured on a CNC plate, ready for precise machining and shaping.

4.4.3 What is Basic CNC Processing?

Basic CNC processing involves simple operations like drilling grip-pin holes in flat pedals. It uses simpler machines with basic up-and-down motion.

4.4.4 How is Basic CNC Processing Used in Pedal Manufacturing?

Machines are set up to drill multiple grip-pin holes, processing two pedals at a time. Fluid lubricates and cools the bits, preventing debris from being ejected.

4.5 What Role Does Fluid Play in CNC Machining?

Fluid lubricates and cools the cutting bits, preventing debris from being ejected and capturing offcuts. This fluid is filtered and recirculated, minimizing waste.

5. Demystifying the Assembly Stage

The assembly stage combines processed components to create complete pedal sets. This process is crucial for ensuring all parts fit together perfectly.

5.1 How is Assembly Organized in Pedal Manufacturing?

Assembly is typically carried out on short production lines with one or two personnel. Materials enter at one end, are assembled, and then packaged for shipping.

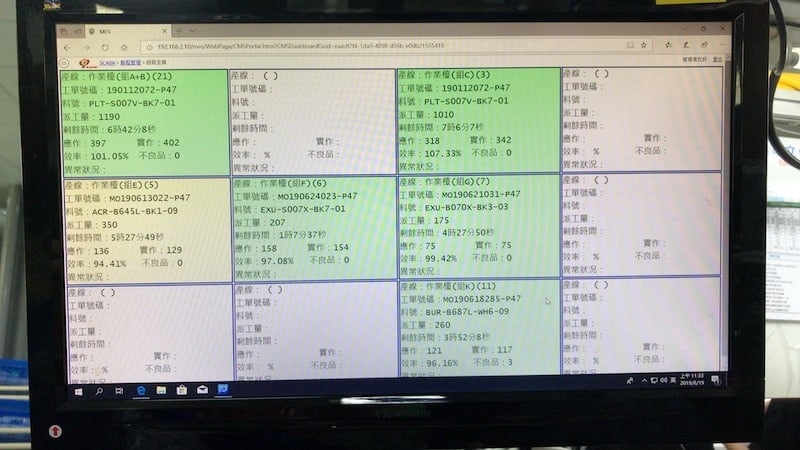

5.2 What is the Role of the MES Platform in Assembly?

The MES (Manufacturing Execution System) platform manages and maximizes production across the assembly area. It monitors production rates and identifies bottlenecks.

MES Monitor

MES Monitor

Alt: A manufacturing execution system (MES) monitor displaying real-time production data and efficiency metrics.

5.3 What Does Pedal Body Assembly Involve?

Pedal body assembly involves installing the axle, injecting grease, and pressing bearings into position. The axle bolt is tightened to tolerance, and the end nut is closed up.

5.4 What is the Focus of Advanced Customized Automation in Pedal Manufacturing?

Advanced customized automation aims to cut costs and deliver higher-quality products. This involves building machines for automating tasks like installing cleat brackets.

5.5 How Does Automated Screw Delivery Work?

Automated screw delivery uses machines that load screws into a tray and feed them to an applicator. This allows operators to quickly fasten brackets to pedal bodies.

6. Understanding the Rigorous Testing Stage

The testing stage ensures the durability and longevity of bike pedals. This phase is vital for guaranteeing quality and safety.

6.1 What are the Main Components Tested in Pedal Manufacturing?

The main components tested are sealed bearing durability and axle strength. These tests ensure the pedals can withstand rigorous use.

6.2 How is Sealed Bearing Longevity Tested?

Sealed bearing longevity is tested to ensure bearings don’t grind themselves to pieces prematurely. The ISO requirement is 100,000 cycles, but SCADA tests to 1,000,000 cycles.

Pedal Testing Machine

Pedal Testing Machine

Alt: A pedal testing machine running durability tests on sealed bearings to ensure longevity and performance.

6.3 How is Axle Strength and Durability Tested?

Axle strength is tested by applying force to the pedal body. A quality axle should bend but not snap under pressure, simulating impacts on rough trails.

6.4 Why is Axle Strength Important for Mountain Bike Pedals?

Mountain bike pedals are vulnerable to impacts. Testing ensures the axle can withstand forces generated from hitting rocks, preventing failure.

7. What are the Benefits of Exploring usabikers.net?

Exploring usabikers.net provides access to comprehensive information, a vibrant biker community, and continuous updates on motorcycle culture. It’s a great online destination for those who are interested in learning more about bikes.

7.1 What Unique Features Does usabikers.net Offer?

usabikers.net offers a rich source of information, a strong biker community, and up-to-date content on motorcycle culture. Here are some details.

- Comprehensive Information: Detailed articles and reviews on various motorcycle topics.

- Vibrant Community: A platform to connect and share experiences with fellow bikers.

- Continuous Updates: Regular updates on new models, events, and regulations.

7.2 How Does usabikers.net Support Small, Growing Brands?

SCADA aims to service both big and small brands, adapting procedures to accept small orders. This makes them unique among pedal manufacturers.

7.3 How Can I Get in Touch for Quality Pedals?

If you’re a brand looking for quality pedals, get in touch with SCADA to discuss your needs and explore potential collaborations.

8. FAQs About Bike Pedal Manufacturing

Do you still have questions about the process of how bike pedals are made? Let’s explore these frequently asked questions.

8.1 What materials are commonly used to manufacture bike pedals?

Bike pedals are commonly made from aluminum, nylon, and steel. Aluminum is favored for its light weight and durability, nylon for its cost-effectiveness, and steel for its strength.

8.2 How does CNC machining improve the quality of bike pedals?

CNC machining improves quality by ensuring precision and consistency in the manufacturing process. It allows for complex designs and tight tolerances, resulting in high-performance pedals.

8.3 What is the typical lifespan of a bike pedal bearing?

The lifespan of a bike pedal bearing varies depending on usage and maintenance. High-quality sealed bearings can last for several years with proper care.

8.4 How often should bike pedals be serviced?

Bike pedals should be serviced at least once a year, or more frequently if you ride in harsh conditions. Regular maintenance includes cleaning, lubricating, and checking for wear.

8.5 What are the key factors that affect the durability of bike pedals?

Key factors affecting durability include material quality, manufacturing precision, and riding conditions. High-quality materials and precise manufacturing result in more durable pedals.

8.6 Can bike pedal designs be customized?

Yes, bike pedal designs can be customized using CAD software and CNC machining. This allows manufacturers to create unique and specialized pedals.

8.7 What is the importance of proper pedal installation?

Proper pedal installation is crucial for safety and performance. Incorrectly installed pedals can lead to discomfort, damage, or even accidents.

8.8 How do manufacturers ensure bike pedals meet safety standards?

Manufacturers ensure safety standards by conducting rigorous testing, including bearing longevity and axle strength tests. These tests simulate real-world conditions to ensure pedals can withstand typical use.

8.9 What are the latest innovations in bike pedal technology?

Latest innovations include improved bearing designs, lighter materials, and advanced cleat systems. These innovations aim to enhance performance, comfort, and durability.

8.10 How does the assembly process contribute to the overall quality of bike pedals?

The assembly process ensures all components fit together perfectly and function as intended. Proper assembly is essential for the overall quality, performance, and longevity of bike pedals.

Understanding how bike pedals are made provides valuable insight into the meticulous processes that ensure quality and performance. From design to testing, each stage is crucial. At usabikers.net, we bring you closer to the world of motorcycle and bicycle manufacturing.

Ready to dive deeper? Explore usabikers.net for more articles, discussions, and community insights. Whether you’re a seasoned biker or just starting out, our platform offers a wealth of information to fuel your passion. Join our community today and share your experiences, ask questions, and connect with fellow enthusiasts. Don’t miss out on the latest trends, tips, and stories from the heart of the biker world. Visit usabikers.net now and become part of our growing family.