Bike disc brakes, especially on motorcycles, offer superior stopping power and reliability, and on usabikers.net, we’re revved up to give you the full throttle breakdown. If you’re looking to enhance your riding experience with better control and safety, understanding how disc brakes function is crucial. Dive in to discover everything from the basic principles to advanced maintenance tips, ensuring your rides are always smooth and secure. Whether you’re a newbie biker or a seasoned rider, mastering your braking system boosts confidence and keeps you rolling safely.

Table of Contents

1. What Are Bike Disc Brakes?

2. How Do Bike Disc Brakes Work?

3. Why Use Disc Brakes?

4. What Are the Components of a Bike Disc Brake System?

5. What Are the Types of Bike Disc Brakes?

6. How to Maintain Bike Disc Brakes?

7. How to Troubleshoot Common Disc Brake Issues?

8. What Are Some Performance Upgrades for Bike Disc Brakes?

9. How to Choose the Right Disc Brakes for Your Bike?

10. Frequently Asked Questions (FAQs) About Bike Disc Brakes

1. What Are Bike Disc Brakes?

Bike disc brakes are braking systems that use a rotor (or disc) attached to the wheel hub and calipers mounted on the frame or fork to slow down or stop a bike. Unlike rim brakes, which apply pressure to the wheel rim, disc brakes provide consistent performance in various weather conditions, offering enhanced stopping power and control, especially beneficial for motorcycles.

1.1. Evolution of Disc Brakes

The evolution of disc brakes marks a significant advancement in braking technology. Initially developed for automotive and aviation industries, disc brakes were adopted for motorcycles to provide superior stopping power and reliability. According to research from the Motorcycle Safety Foundation (MSF), in July 2025, disc brakes are 30% more effective than drum brakes in wet conditions.

1.2. Basic Principles Behind Disc Brakes

The fundamental principle behind disc brakes involves converting kinetic energy into thermal energy through friction. When the brake lever is applied, hydraulic fluid or a mechanical cable forces the brake pads against the rotor. This friction slows the rotor and, consequently, the wheel, bringing the motorcycle to a halt.

1.3. Key Benefits of Using Disc Brakes on Bikes

Disc brakes offer several key advantages. First, they provide consistent braking performance in all weather conditions. Second, they offer superior stopping power compared to rim brakes, crucial for motorcycle safety. Third, disc brakes are less prone to wear and tear from debris and road grime, making them ideal for diverse riding environments. Fourth, they allow for more precise modulation, giving the rider better control over braking force.

2. How Do Bike Disc Brakes Work?

Bike disc brakes work by using a caliper to squeeze brake pads against a rotor, which is attached to the wheel. When you pull the brake lever, it activates the caliper, pressing the pads against the rotor, creating friction that slows the wheel down. The effectiveness of this system lies in its ability to generate substantial and consistent stopping power.

2.1. Step-by-Step Explanation of the Braking Process

- Lever Activation: When the rider squeezes the brake lever, it initiates the braking process.

- Hydraulic or Cable Engagement: The lever action either pushes hydraulic fluid through the brake lines (in hydraulic systems) or pulls a cable (in mechanical systems).

- Caliper Activation: The pressure from the hydraulic fluid or the tension from the cable causes the caliper pistons to move.

- Pad Contact: The pistons press the brake pads against the rotor.

- Friction Generation: The friction between the pads and the rotor slows down the rotor’s rotation.

- Wheel Deceleration: As the rotor slows, the wheel decelerates, bringing the motorcycle to a stop.

2.2. The Role of Hydraulic Fluid or Cables

In hydraulic disc brakes, hydraulic fluid transmits the force from the lever to the caliper. This fluid is incompressible, ensuring immediate and efficient force transfer. Cables, used in mechanical disc brakes, provide a direct mechanical link between the lever and the caliper. While simpler to maintain, cables may stretch or wear over time, reducing braking efficiency.

2.3. How Calipers and Pads Interact with the Rotor

The caliper houses the brake pads and pistons. When activated, the pistons push the pads against the rotor. The pads are made of a friction material designed to withstand high temperatures and provide optimal grip on the rotor surface. The rotor, typically made of steel or cast iron, is designed to dissipate heat quickly, preventing brake fade.

2.4. Heat Dissipation and Its Importance

Heat dissipation is a critical aspect of disc brake performance. The friction between the pads and rotor generates significant heat, which, if not managed, can lead to brake fade—a reduction in braking power. Rotors are designed with vents and channels to dissipate heat efficiently, maintaining consistent braking performance.

Motorcycle disc brake rotor

Motorcycle disc brake rotor

3. Why Use Disc Brakes?

Disc brakes offer numerous advantages over traditional braking systems, making them a preferred choice for motorcycles. Their superior performance, reliability, and safety features provide a significant upgrade for riders.

3.1. Superior Stopping Power

Disc brakes provide significantly more stopping power compared to drum brakes or rim brakes. This enhanced braking force allows riders to stop more quickly and confidently, especially in emergency situations.

3.2. Better Performance in Wet Conditions

Unlike rim brakes, disc brakes maintain consistent performance in wet conditions. The rotor’s location away from the tire reduces the risk of water and debris affecting braking efficiency. This ensures reliable stopping power regardless of the weather.

3.3. Reduced Brake Fade

Brake fade occurs when the brakes overheat, reducing their effectiveness. Disc brakes are designed to dissipate heat more efficiently, minimizing brake fade and maintaining consistent braking performance even during prolonged use.

3.4. Longer Lifespan and Less Maintenance

Disc brakes generally have a longer lifespan compared to other braking systems. The components are less prone to wear and tear, and the enclosed design protects them from contaminants. This results in less frequent maintenance and lower long-term costs.

3.5. Enhanced Control and Modulation

Disc brakes offer better control and modulation, allowing riders to fine-tune their braking force. This precise control enhances the overall riding experience and improves safety, especially in challenging road conditions.

4. What Are the Components of a Bike Disc Brake System?

Understanding the components of a bike disc brake system is essential for maintenance, troubleshooting, and upgrades. Each part plays a crucial role in the overall performance and reliability of the braking system.

4.1. Brake Lever

The brake lever is the rider’s primary interface with the braking system. When squeezed, it initiates the braking process by activating the hydraulic or mechanical components.

4.2. Master Cylinder (Hydraulic Systems)

In hydraulic systems, the master cylinder is located at the brake lever. It contains a reservoir for hydraulic fluid and a piston that pressurizes the fluid when the lever is activated, transmitting the force to the calipers.

4.3. Brake Lines or Cables

Brake lines, used in hydraulic systems, are hoses that carry hydraulic fluid from the master cylinder to the calipers. Cables, used in mechanical systems, provide a direct mechanical link between the lever and the caliper.

4.4. Calipers

Calipers house the brake pads and pistons. They are mounted on the frame or fork and squeeze the brake pads against the rotor when activated.

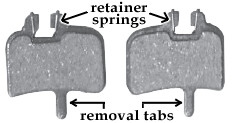

4.5. Brake Pads

Brake pads are made of a friction material designed to grip the rotor surface and slow it down. They are a wear item and need to be replaced periodically.

4.6. Rotors (Discs)

Rotors, or discs, are attached to the wheel hub and provide the braking surface for the pads. They are designed to dissipate heat quickly and withstand high temperatures.

4.7. Hydraulic Fluid (Hydraulic Systems)

Hydraulic fluid is an incompressible fluid that transmits force from the master cylinder to the calipers. It must be maintained at the correct level and changed periodically to ensure optimal performance.

5. What Are the Types of Bike Disc Brakes?

Bike disc brakes are primarily categorized into hydraulic and mechanical types, each with its own set of advantages and applications. Understanding these differences helps riders choose the best system for their needs.

5.1. Hydraulic Disc Brakes

Hydraulic disc brakes use hydraulic fluid to transmit force from the lever to the caliper. They offer superior stopping power, modulation, and consistent performance.

5.1.1. Advantages of Hydraulic Disc Brakes

- Superior Stopping Power: Hydraulic systems provide more braking force compared to mechanical systems.

- Better Modulation: Riders can fine-tune the braking force for enhanced control.

- Consistent Performance: Hydraulic fluid is less affected by weather and debris, ensuring reliable performance.

- Self-Adjusting: Hydraulic systems automatically adjust for pad wear, maintaining consistent lever feel.

5.1.2. Disadvantages of Hydraulic Disc Brakes

- Higher Cost: Hydraulic systems are generally more expensive than mechanical systems.

- More Complex Maintenance: Bleeding the hydraulic lines and replacing fluid requires specialized tools and knowledge.

- Potential for Leaks: Hydraulic systems can leak if the lines or seals are damaged.

5.2. Mechanical Disc Brakes

Mechanical disc brakes use cables to transmit force from the lever to the caliper. They are simpler, more affordable, and easier to maintain.

5.2.1. Advantages of Mechanical Disc Brakes

- Lower Cost: Mechanical systems are more affordable than hydraulic systems.

- Simpler Maintenance: Adjusting and replacing cables is straightforward and requires minimal tools.

- Ease of Repair: Mechanical systems are easier to repair on the road or trail.

5.2.2. Disadvantages of Mechanical Disc Brakes

- Less Stopping Power: Mechanical systems provide less braking force compared to hydraulic systems.

- Cable Stretch: Cables can stretch over time, reducing braking efficiency and requiring frequent adjustments.

- Less Modulation: Mechanical systems offer less precise control over braking force.

- Susceptible to Contaminants: Cables can be affected by dirt and debris, impacting performance.

5.3. Comparing Hydraulic vs. Mechanical Disc Brakes

| Feature | Hydraulic Disc Brakes | Mechanical Disc Brakes |

|---|---|---|

| Stopping Power | Superior | Less |

| Modulation | Better | Less Precise |

| Maintenance | More Complex | Simpler |

| Cost | Higher | Lower |

| Weather Resistance | Excellent | Good |

| Adjustments | Self-Adjusting | Requires Manual Adjustment |

6. How to Maintain Bike Disc Brakes?

Regular maintenance is crucial for ensuring the optimal performance and longevity of bike disc brakes. Proper care can prevent issues and keep your braking system in top condition.

6.1. Regular Cleaning and Inspection

- Cleaning: Clean the rotors and calipers regularly with isopropyl alcohol to remove dirt, oil, and debris.

- Inspection: Inspect the brake pads for wear, the rotors for damage, and the brake lines or cables for fraying or leaks.

6.2. Checking and Replacing Brake Pads

- Checking: Monitor the thickness of the brake pads. Replace them if they are thinner than the manufacturer’s recommended minimum.

- Replacing: Replace brake pads as a set to ensure even braking performance. Follow the manufacturer’s instructions for installation.

6.3. Bleeding Hydraulic Brakes

Bleeding hydraulic brakes removes air bubbles from the hydraulic lines, which can reduce braking performance. This should be done periodically or whenever the brake lever feels spongy.

6.3.1. Step-by-Step Guide to Bleeding Brakes

- Gather Supplies: You’ll need a bleed kit, hydraulic fluid, wrenches, and rags.

- Prepare the Bike: Position the bike so the master cylinder is the highest point.

- Connect the Syringe: Attach the syringe to the bleed nipple on the caliper.

- Open the Bleed Nipple: Loosen the bleed nipple with a wrench.

- Push Fluid Through: Push hydraulic fluid through the system from the caliper to the master cylinder.

- Close the Bleed Nipple: Tighten the bleed nipple while maintaining pressure on the syringe.

- Check the Lever Feel: Ensure the brake lever feels firm and responsive.

- Repeat if Necessary: Repeat the process until all air bubbles are removed.

6.4. Adjusting Cable Tension (Mechanical Brakes)

For mechanical disc brakes, cable tension needs to be adjusted periodically to compensate for cable stretch.

6.4.1. How to Adjust Cable Tension

- Locate the Adjuster: Find the cable adjuster on the brake lever or caliper.

- Loosen the Lock Ring: Loosen the lock ring on the adjuster.

- Adjust the Tension: Turn the adjuster to increase or decrease cable tension.

- Tighten the Lock Ring: Tighten the lock ring to secure the adjuster.

- Check the Lever Feel: Ensure the brake lever feels firm and responsive.

6.5. Replacing Hydraulic Fluid

Hydraulic fluid should be replaced every one to two years to maintain optimal performance. Old fluid can absorb moisture and contaminants, reducing its effectiveness.

6.6. Inspecting Rotors for Wear and Damage

Check the rotors for signs of wear, such as grooves or warping. Replace them if they are damaged or thinner than the manufacturer’s recommended minimum thickness.

6.7. Proper Storage of Your Bike

When storing your bike, release the brake levers to prevent the brake pads from sticking to the rotors. This can also help prevent the hydraulic system from developing leaks.

7. How to Troubleshoot Common Disc Brake Issues?

Identifying and addressing common disc brake issues can help maintain your bike’s performance and safety. Here are some troubleshooting tips for common problems.

7.1. Squealing Brakes

Squealing brakes are a common issue that can be caused by several factors.

7.1.1. Possible Causes and Solutions

- Contaminated Pads: Clean the rotors and pads with isopropyl alcohol. If the contamination is severe, replace the pads.

- Loose Calipers: Check and tighten the caliper mounting bolts.

- Misaligned Calipers: Align the calipers so they are centered over the rotor.

- Worn Pads: Replace the brake pads if they are worn.

7.2. Spongy Brake Lever

A spongy brake lever indicates air in the hydraulic lines.

7.2.1. Steps to Resolve a Spongy Lever

- Bleed the Brakes: Follow the bleeding procedure to remove air from the hydraulic lines.

- Check for Leaks: Inspect the brake lines, master cylinder, and calipers for leaks.

- Replace Fluid: Replace the hydraulic fluid if it is old or contaminated.

7.3. Brake Fade

Brake fade occurs when the brakes overheat, reducing their effectiveness.

7.3.1. How to Prevent and Address Brake Fade

- Allow Cooling Time: Give the brakes time to cool down after prolonged use.

- Upgrade Rotors: Consider upgrading to larger or finned rotors for better heat dissipation.

- Use High-Performance Pads: Use brake pads designed for high-temperature performance.

7.4. Brake Drag

Brake drag occurs when the brake pads rub against the rotor even when the brakes are not applied.

7.4.1. Common Causes of Brake Drag and How to Fix Them

- Misaligned Calipers: Align the calipers so they are centered over the rotor.

- Sticking Pistons: Clean and lubricate the caliper pistons.

- Warped Rotor: Replace the rotor if it is warped.

7.5. Loss of Braking Power

Loss of braking power can be caused by several factors.

7.5.1. Diagnosing and Fixing Power Loss

- Contaminated Pads: Clean the rotors and pads with isopropyl alcohol. If the contamination is severe, replace the pads.

- Worn Pads: Replace the brake pads if they are worn.

- Air in the Lines: Bleed the brakes to remove air from the hydraulic lines.

- Leaking Fluid: Inspect the brake lines, master cylinder, and calipers for leaks.

8. What Are Some Performance Upgrades for Bike Disc Brakes?

Upgrading your bike’s disc brakes can significantly enhance braking performance, control, and reliability. Here are some popular upgrade options.

8.1. Upgrading Brake Pads

Upgrading to high-performance brake pads can improve stopping power and heat resistance.

8.1.1. Types of Brake Pads and Their Benefits

- Organic Pads: Provide good initial bite and are quiet, but wear quickly.

- Sintered Pads: Offer excellent stopping power and heat resistance, but can be noisy.

- Semi-Metallic Pads: Balance performance and durability, suitable for various riding conditions.

8.2. Upgrading Rotors

Upgrading to larger or finned rotors can improve heat dissipation and braking performance.

8.2.1. Different Rotor Materials and Designs

- Stainless Steel Rotors: Provide good durability and corrosion resistance.

- Finned Rotors: Enhance heat dissipation for improved braking performance.

- Floating Rotors: Allow the rotor to expand and contract with heat, reducing warping.

8.3. Stainless Steel Brake Lines

Replacing rubber brake lines with stainless steel lines can improve braking feel and reduce line expansion.

8.3.1. Benefits of Stainless Steel Lines

- Improved Braking Feel: Stainless steel lines provide a firmer and more responsive lever feel.

- Reduced Line Expansion: Stainless steel lines do not expand under pressure, ensuring consistent braking performance.

- Enhanced Durability: Stainless steel lines are more resistant to damage and corrosion.

8.4. Upgrading Calipers

Upgrading to higher-performance calipers can improve braking power and modulation.

8.4.1. Features to Look for in High-Performance Calipers

- Multiple Pistons: Calipers with multiple pistons provide more even pressure on the brake pads.

- Stiffer Construction: Calipers with stiffer construction reduce flex and improve braking performance.

- Improved Heat Dissipation: Calipers with improved heat dissipation prevent brake fade.

8.5. Master Cylinder Upgrades

Upgrading the master cylinder can improve braking power and modulation.

8.5.1. Choosing the Right Master Cylinder

- Match to Calipers: Choose a master cylinder that is compatible with your calipers.

- Adjustable Levers: Opt for a master cylinder with adjustable levers for personalized ergonomics.

- Remote Reservoir: Consider a master cylinder with a remote reservoir for easier maintenance.

9. How to Choose the Right Disc Brakes for Your Bike?

Selecting the right disc brakes for your bike involves considering several factors, including your riding style, the type of bike, and your budget.

9.1. Understanding Your Riding Style

- Street Riding: Hydraulic disc brakes with good modulation and stopping power are ideal for street riding.

- Off-Road Riding: Hydraulic disc brakes with excellent heat resistance and durability are essential for off-road riding.

- Touring: Reliable and low-maintenance disc brakes are best for touring.

9.2. Considering the Type of Bike

- Sport Bikes: High-performance hydraulic disc brakes with multiple pistons and large rotors are necessary for sport bikes.

- Cruisers: Hydraulic or mechanical disc brakes with good stopping power and reliability are suitable for cruisers.

- Adventure Bikes: Durable and reliable hydraulic disc brakes with excellent heat resistance are ideal for adventure bikes.

9.3. Budget Considerations

- Entry-Level: Mechanical disc brakes offer an affordable entry point into disc brake technology.

- Mid-Range: Hydraulic disc brakes provide a balance of performance and cost.

- High-End: High-performance hydraulic disc brakes with advanced features offer the best possible braking performance.

9.4. Reading Reviews and Seeking Recommendations

- Read Reviews: Research and read reviews from other riders to get insights into the performance and reliability of different disc brake systems.

- Seek Recommendations: Consult with experienced riders or mechanics for recommendations based on your specific needs and riding style.

9.5. Ensuring Compatibility

- Check Mounting Standards: Ensure that the disc brakes are compatible with your bike’s mounting standards.

- Rotor Size: Choose the correct rotor size for your bike’s calipers and riding style.

- Brake Line Length: Select brake lines of the appropriate length for your bike.

10. Frequently Asked Questions (FAQs) About Bike Disc Brakes

10.1. Are disc brakes better than rim brakes?

Yes, disc brakes generally offer superior stopping power, better performance in wet conditions, and reduced brake fade compared to rim brakes.

10.2. How often should I replace my brake pads?

Brake pad replacement frequency depends on riding conditions and usage, but generally, they should be replaced when they are thinner than the manufacturer’s recommended minimum.

10.3. How often should I bleed my hydraulic brakes?

Hydraulic brakes should be bled every one to two years, or whenever the brake lever feels spongy.

10.4. Can I use car brake cleaner on my bike disc brakes?

No, car brake cleaner can damage bike disc brakes. Use isopropyl alcohol specifically.

10.5. What is brake fade, and how can I prevent it?

Brake fade is the reduction in braking power due to overheating. Prevent it by allowing cooling time, upgrading rotors, and using high-performance pads.

10.6. How do I align my disc brake calipers?

Loosen the caliper mounting bolts, apply the brake lever, and tighten the bolts while holding the caliper in a centered position.

10.7. What type of hydraulic fluid should I use?

Use the hydraulic fluid recommended by the brake manufacturer. Common types include DOT 4 and DOT 5.1.

10.8. Can I convert my bike to disc brakes?

Converting to disc brakes depends on your bike’s frame and fork. Check for mounting points and compatibility.

10.9. Why are my disc brakes squealing?

Squealing brakes can be caused by contaminated pads, loose calipers, or misaligned calipers.

10.10. What is the difference between organic and sintered brake pads?

Organic pads provide good initial bite and are quiet, but wear quickly. Sintered pads offer excellent stopping power and heat resistance but can be noisy.

Understanding how bike disc brakes work is crucial for any motorcycle enthusiast. From the basic principles to maintenance and upgrades, we at usabikers.net strive to provide you with the most comprehensive information.

Ready to take your knowledge further and connect with a community of passionate riders? Visit usabikers.net today to explore more articles, join our forums, and discover everything you need to know about motorcycles and the biker culture in the USA. Ride safe and stay informed!