Are you fascinated by the intricate workings of your motorcycle? The clutch is a vital component that allows you to control the power flow from the engine to the wheels. At usabikers.net, we break down the mechanics of “How Does A Bike Clutch Work” in an easy-to-understand manner, helping you become a more knowledgeable and confident rider. Join us as we explore the mechanics of motorcycle clutches, clutch control, and the advantages of both wet and dry clutches, all tailored for the American biker community.

1. What Is a Motorcycle Clutch and Why Is It Important?

A motorcycle clutch is a mechanical device that connects and disconnects the engine from the transmission, allowing the rider to smoothly engage gears and control the bike’s power delivery. Without a clutch, starting, stopping, and shifting gears would be nearly impossible, making it a fundamental component for any motorcycle.

The clutch’s primary function is to temporarily interrupt the power flow from the engine to the transmission, allowing the rider to change gears without stalling the engine or damaging the drivetrain. This is crucial for smooth acceleration, deceleration, and overall control of the motorcycle. The motorcycle clutch is essential for controlling power and gear changes, enabling smooth transitions and preventing engine stalls or damage.

1.1. Understanding the Basic Function of a Motorcycle Clutch

The basic function of a motorcycle clutch involves engaging and disengaging the engine from the transmission. When the clutch is engaged (lever released), power flows from the engine to the transmission, propelling the motorcycle forward. When the clutch is disengaged (lever pulled), the connection is broken, allowing the rider to shift gears or come to a stop without stalling.

1.2. Why a Clutch Is Essential for Smooth Riding

A clutch is essential for smooth riding because it allows for controlled engagement of power, preventing abrupt starts and stops. It also facilitates seamless gear changes by momentarily disconnecting the engine, reducing wear and tear on the transmission components. According to the Motorcycle Safety Foundation (MSF), proper clutch use is crucial for maintaining control and balance, particularly during low-speed maneuvers.

1.3. The Role of the Clutch in Gear Shifting

The clutch plays a pivotal role in gear shifting by allowing the rider to select a different gear ratio without causing damage to the transmission. When shifting gears, the clutch disengages the engine, allowing the rider to select the next gear, and then smoothly re-engages to resume power delivery. This process ensures a smooth and efficient transition between gears, optimizing performance and fuel efficiency.

2. Types of Motorcycle Clutches: Wet vs. Dry

Motorcycle clutches come in two primary types: wet and dry. Wet clutches operate in an oil bath, providing lubrication and cooling, while dry clutches operate without lubrication, offering higher friction but requiring more careful maintenance. Each type has its advantages and disadvantages, making them suitable for different applications and riding styles.

Understanding the differences between wet and dry clutches can help you make an informed decision when purchasing a motorcycle or upgrading your clutch system. Both types of clutches have their unique advantages and are used in various motorcycle models based on their specific requirements.

2.1. Wet Clutches: How They Work and Their Benefits

Wet clutches operate submerged in engine oil, which provides cooling, lubrication, and smooth engagement. This design is common in most motorcycles due to its durability and reduced maintenance requirements. The oil helps dissipate heat generated by friction, preventing the clutch plates from overheating and wearing out quickly.

2.1.1. Advantages of Wet Clutches

- Cooling: Oil submersion dissipates heat effectively.

- Lubrication: Reduces wear and tear on clutch components.

- Smooth Engagement: Provides a smoother transition of power.

- Durability: Lasts longer due to reduced heat and wear.

2.1.2. Disadvantages of Wet Clutches

- Power Loss: Oil drag can reduce overall power transmission efficiency.

- Complexity: Requires a sealed system to contain the oil.

- Contamination: Clutch debris can contaminate engine oil.

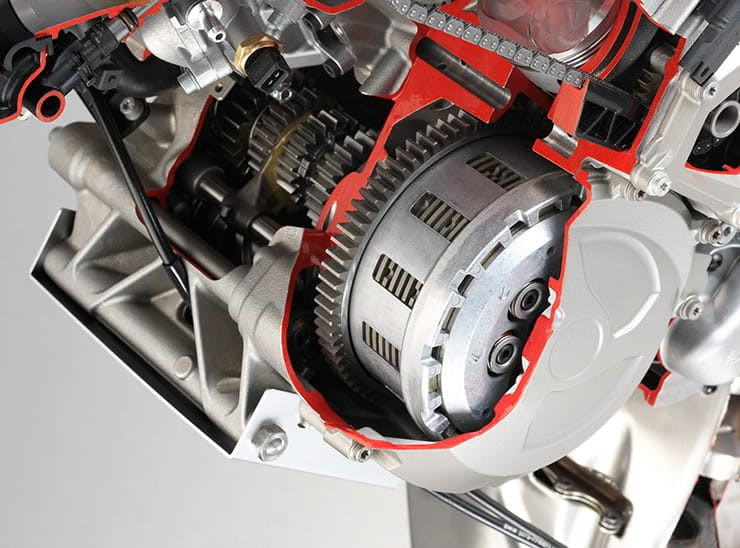

Wet clutch components

Wet clutch components

2.2. Dry Clutches: How They Work and Their Benefits

Dry clutches operate without any lubrication, resulting in higher friction and more direct power transfer. This type of clutch is commonly found in high-performance motorcycles and racing applications where maximum power delivery is crucial. However, dry clutches require more frequent maintenance and are more susceptible to wear and tear.

2.2.1. Advantages of Dry Clutches

- Higher Friction: Provides more direct power transfer.

- Lighter Weight: Generally lighter than wet clutches due to the absence of oil.

- No Oil Contamination: Clutch debris does not contaminate engine oil.

2.2.2. Disadvantages of Dry Clutches

- Increased Wear: Lack of lubrication leads to faster wear.

- Noise: Can be noisier than wet clutches due to rattling plates.

- Maintenance: Requires more frequent maintenance and adjustments.

- Heat Sensitivity: More prone to overheating under heavy use.

2.3. Comparing Wet and Dry Clutches: Which Is Best for You?

The choice between wet and dry clutches depends on your riding style, the type of motorcycle, and your maintenance preferences. Wet clutches are ideal for everyday riding and touring due to their durability and low maintenance, while dry clutches are better suited for high-performance applications where maximum power delivery is essential. Consider the following factors when making your decision:

- Riding Style: Aggressive riding may benefit from a dry clutch, while casual riding is better suited for a wet clutch.

- Maintenance: Dry clutches require more frequent maintenance.

- Performance: Dry clutches offer better power transfer but may wear out faster.

- Noise: Dry clutches are generally noisier than wet clutches.

| Feature | Wet Clutch | Dry Clutch |

|---|---|---|

| Lubrication | Operates in oil | Operates without oil |

| Cooling | Excellent | Poor |

| Maintenance | Low | High |

| Power Transfer | Slightly less efficient | More efficient |

| Noise | Quieter | Noisier |

| Durability | High | Lower |

| Best For | Everyday riding, touring | High-performance, racing |

3. How a Multi-Plate Clutch Works

A multi-plate clutch uses multiple friction plates to increase the surface area, allowing for more efficient power transfer and better heat dissipation. This design is common in modern motorcycles, providing a compact and reliable solution for handling high horsepower engines. Understanding how a multi-plate clutch works can help you appreciate the engineering behind your motorcycle’s performance.

The multi-plate design allows for a smaller clutch assembly while still providing sufficient friction to handle the engine’s power. This is especially important in motorcycles, where space is limited.

3.1. The Components of a Multi-Plate Clutch

A multi-plate clutch consists of several key components, including:

- Friction Plates: These plates are lined with friction material and are responsible for engaging with the steel plates to transfer power.

- Steel Plates: These plates are smooth and provide a surface for the friction plates to grip onto.

- Clutch Basket: This houses the clutch plates and is connected to the engine’s crankshaft.

- Pressure Plate: This plate applies pressure to the clutch pack, engaging the clutch.

- Clutch Springs: These springs provide the force needed to engage the clutch and are released when the clutch lever is pulled.

3.2. The Engagement and Disengagement Process

The engagement and disengagement process of a multi-plate clutch involves the following steps:

- Engagement: When the clutch lever is released, the clutch springs push the pressure plate against the clutch pack, clamping the friction and steel plates together. This creates friction, allowing power to flow from the engine to the transmission.

- Disengagement: When the clutch lever is pulled, the clutch cable or hydraulic system pulls the pressure plate away from the clutch pack, releasing the clamping force. This separates the friction and steel plates, interrupting the power flow and allowing the rider to shift gears or come to a stop.

3.3. Advantages of Using Multiple Plates

Using multiple plates in a clutch system offers several advantages:

- Increased Surface Area: More plates provide a larger surface area for friction, allowing for more efficient power transfer.

- Better Heat Dissipation: The increased surface area also helps dissipate heat more effectively, preventing clutch fade and prolonging the life of the clutch.

- Compact Design: Multi-plate clutches can be more compact than single-plate designs, making them ideal for motorcycles with limited space.

- Smooth Engagement: The multiple plates allow for a smoother and more controlled engagement, improving the overall riding experience.

4. Manual vs. Automatic Clutches: Which Is Right for You?

Motorcycles come with either manual or automatic clutches, each offering a unique riding experience. Manual clutches require the rider to manually engage and disengage the clutch using a lever, while automatic clutches handle the engagement automatically, simplifying the riding process. Understanding the differences between these two types can help you choose the right motorcycle for your needs.

Manual clutches offer more control and are favored by experienced riders, while automatic clutches provide ease of use and are popular among beginners and those seeking a more relaxed riding experience.

4.1. Manual Clutches: How They Work and Their Benefits

Manual clutches require the rider to manually control the engagement and disengagement of the clutch using a lever on the handlebar. This type of clutch provides precise control over power delivery and is favored by experienced riders who enjoy the feeling of direct connection with the motorcycle.

4.1.1. The Mechanics of a Manual Clutch System

The manual clutch system consists of a clutch lever, cable or hydraulic system, pressure plate, clutch plates, and clutch springs. When the lever is pulled, the cable or hydraulic system disengages the pressure plate, separating the clutch plates and interrupting the power flow. Releasing the lever allows the springs to re-engage the pressure plate, clamping the clutch plates together and resuming power delivery.

4.1.2. Advantages of Manual Clutches

- Precise Control: Offers precise control over power delivery.

- Engagement: Allows for better control during starts, stops, and gear changes.

- Feedback: Provides direct feedback from the engine, enhancing the riding experience.

4.1.3. Disadvantages of Manual Clutches

- Learning Curve: Requires practice and skill to master smooth clutch operation.

- Fatigue: Can be tiring during long rides, especially in heavy traffic.

- Complexity: Requires coordination between the clutch, throttle, and gear shifter.

4.2. Automatic Clutches: How They Work and Their Benefits

Automatic clutches, also known as semi-automatic clutches, automate the engagement and disengagement process, eliminating the need for a clutch lever. This type of clutch simplifies the riding experience and is popular among beginners and those seeking a more relaxed ride.

4.2.1. The Mechanics of an Automatic Clutch System

Automatic clutch systems use centrifugal force or other mechanical means to engage and disengage the clutch based on engine speed. As the engine speed increases, the centrifugal force causes the clutch plates to engage, transmitting power to the transmission. When the engine speed decreases, the clutch plates disengage, interrupting the power flow.

4.2.2. Advantages of Automatic Clutches

- Ease of Use: Simplifies riding, especially for beginners.

- Reduced Fatigue: Eliminates the need to operate a clutch lever, reducing fatigue.

- Smooth Transitions: Provides smooth and seamless gear changes.

4.2.3. Disadvantages of Automatic Clutches

- Less Control: Offers less precise control over power delivery.

- Reduced Feedback: Provides less direct feedback from the engine.

- Complexity: Can be more complex mechanically than manual clutches.

4.3. Choosing Between Manual and Automatic Clutches

The choice between manual and automatic clutches depends on your riding experience, preferences, and intended use. Manual clutches are ideal for experienced riders who enjoy the feeling of control and direct connection with the motorcycle, while automatic clutches are better suited for beginners and those seeking a more relaxed and convenient riding experience.

| Feature | Manual Clutch | Automatic Clutch |

|---|---|---|

| Control | High | Lower |

| Learning Curve | Steep | Gentle |

| Fatigue | Higher | Lower |

| Feedback | Direct | Less Direct |

| Best For | Experienced riders, performance riding | Beginners, relaxed riding |

5. Slipper Clutches: What They Are and How They Improve Performance

Slipper clutches are a specialized type of clutch designed to reduce engine braking and improve stability during aggressive downshifting. This technology is commonly found in high-performance motorcycles and racing applications, providing smoother transitions and preventing rear-wheel lockup. Understanding how slipper clutches work can help you appreciate their benefits and consider upgrading your motorcycle.

Slipper clutches allow for smoother downshifts, reducing the risk of wheel hop and maintaining stability, especially during corner entry.

5.1. The Purpose of a Slipper Clutch

The primary purpose of a slipper clutch is to mitigate the effects of engine braking during rapid downshifts. Engine braking occurs when the rider decelerates by releasing the throttle, causing the engine to slow down and transmit that deceleration force to the rear wheel. In extreme cases, this can cause the rear wheel to lock up or hop, leading to a loss of control.

5.2. How a Slipper Clutch Works

A slipper clutch works by allowing the clutch to “slip” or partially disengage when excessive engine braking is detected. This reduces the amount of deceleration force transmitted to the rear wheel, preventing lockup and maintaining stability. The slipper clutch uses a ramped mechanism that allows the clutch plates to separate slightly under high engine braking forces.

5.3. Benefits of Using a Slipper Clutch

- Reduced Engine Braking: Minimizes the effects of engine braking, providing smoother deceleration.

- Improved Stability: Prevents rear-wheel lockup and hopping, enhancing stability during downshifts.

- Faster Cornering: Allows for more aggressive downshifts and corner entry, improving lap times.

- Reduced Stress on Components: Reduces stress on the drivetrain, prolonging the life of the transmission and rear tire.

6. Diagnosing Common Clutch Problems

Identifying and addressing clutch problems early can prevent more significant issues and ensure your motorcycle operates smoothly. Common clutch problems include slipping, sticking, and noisy operation. Understanding the symptoms and causes of these problems can help you diagnose and resolve them effectively.

Regular maintenance and timely repairs are crucial for maintaining the health and performance of your motorcycle’s clutch system.

6.1. Symptoms of a Slipping Clutch

A slipping clutch occurs when the clutch plates fail to engage fully, causing a loss of power and acceleration. Common symptoms of a slipping clutch include:

- High Engine RPM with Slow Acceleration: The engine revs up quickly, but the bike accelerates slowly.

- Burning Smell: A distinct burning smell may be present due to the friction material overheating.

- Difficulty Climbing Hills: The bike struggles to maintain speed when climbing hills.

- Poor Fuel Economy: The engine works harder to maintain speed, resulting in reduced fuel economy.

6.2. Symptoms of a Sticking Clutch

A sticking clutch occurs when the clutch plates fail to disengage fully, making it difficult to shift gears or come to a stop. Common symptoms of a sticking clutch include:

- Difficulty Shifting Gears: Gears are hard to engage, especially when starting from a standstill.

- Bike Creeping Forward: The bike continues to move forward even with the clutch lever pulled.

- Clutch Drag: A feeling of resistance when shifting gears.

- Stalling: The engine stalls when coming to a stop with the clutch lever pulled.

6.3. Symptoms of a Noisy Clutch

A noisy clutch can indicate various problems, ranging from worn clutch plates to a damaged clutch basket. Common symptoms of a noisy clutch include:

- Rattling Noise: A rattling noise when the engine is idling, especially with the clutch lever released.

- Squealing Noise: A high-pitched squealing noise when engaging or disengaging the clutch.

- Grinding Noise: A grinding noise when shifting gears, indicating damaged clutch plates or a worn clutch basket.

- Clunking Noise: A loud clunking noise when engaging the clutch, possibly indicating broken clutch springs.

6.4. Common Causes of Clutch Problems

Several factors can contribute to clutch problems, including:

- Worn Clutch Plates: The friction material on the clutch plates wears down over time, reducing their ability to grip.

- Contaminated Clutch Plates: Oil, dirt, or debris can contaminate the clutch plates, reducing their friction.

- Stretched Clutch Cable: A stretched clutch cable can prevent the clutch from fully disengaging.

- Low Clutch Fluid: Low clutch fluid in hydraulic systems can affect clutch performance.

- Damaged Clutch Springs: Broken or weak clutch springs can reduce the clamping force on the clutch plates.

7. Maintaining Your Motorcycle Clutch

Proper maintenance is essential for prolonging the life of your motorcycle’s clutch and ensuring smooth operation. Regular inspections, adjustments, and fluid changes can help prevent common clutch problems and keep your bike running at its best.

Following a consistent maintenance schedule can save you time and money in the long run by preventing costly repairs and replacements.

7.1. Regular Inspections and Adjustments

Regularly inspect the clutch lever, cable, and related components for wear and tear. Adjust the clutch cable or hydraulic system as needed to maintain proper free play and ensure smooth engagement and disengagement.

7.2. Clutch Cable Lubrication

Lubricate the clutch cable regularly to prevent friction and corrosion. Use a cable lubricator tool to ensure the lubricant reaches the entire length of the cable.

7.3. Fluid Changes for Hydraulic Clutches

For motorcycles with hydraulic clutches, change the clutch fluid regularly according to the manufacturer’s recommendations. This helps maintain proper clutch performance and prevent corrosion.

7.4. Using the Right Oil for Wet Clutches

For motorcycles with wet clutches, use the correct type of engine oil as specified by the manufacturer. Using the wrong oil can cause clutch slippage or damage.

7.5. Replacing Clutch Plates

Replace the clutch plates when they become worn or contaminated. Signs of worn clutch plates include slipping, reduced acceleration, and difficulty climbing hills.

8. Upgrading Your Motorcycle Clutch

Upgrading your motorcycle clutch can improve performance, durability, and overall riding experience. Performance clutch kits, heavy-duty springs, and aftermarket clutch baskets are common upgrades that can enhance your bike’s capabilities.

Consider upgrading your clutch if you frequently ride aggressively, carry heavy loads, or want to improve your bike’s overall performance.

8.1. Performance Clutch Kits

Performance clutch kits typically include upgraded friction plates, steel plates, and clutch springs. These kits are designed to handle higher horsepower and torque, providing improved power transfer and durability.

8.2. Heavy-Duty Clutch Springs

Heavy-duty clutch springs increase the clamping force on the clutch plates, preventing slippage and improving power transfer. These springs are ideal for riders who frequently ride aggressively or carry heavy loads.

8.3. Aftermarket Clutch Baskets

Aftermarket clutch baskets are made from stronger materials than the stock baskets, providing improved durability and resistance to wear. These baskets are a good upgrade for riders who frequently experience clutch problems or want to improve the longevity of their clutch system.

8.4. Slipper Clutch Upgrades

Consider upgrading to a slipper clutch for improved stability and smoother downshifts, especially if you ride aggressively or participate in track days.

9. Clutch Control Techniques for Beginners

Mastering clutch control is essential for becoming a proficient motorcycle rider. Proper clutch control allows for smooth starts, stops, and gear changes, enhancing your confidence and safety on the road.

Practice these techniques in a controlled environment before applying them in real-world riding situations.

9.1. Finding the Friction Zone

The friction zone is the point where the clutch begins to engage, allowing for controlled power delivery. Practice finding the friction zone by slowly releasing the clutch lever until the bike starts to move forward.

9.2. Smooth Starts

To start smoothly, gradually release the clutch lever while simultaneously applying throttle. Avoid releasing the clutch too quickly, which can cause the bike to stall or lurch forward.

9.3. Controlled Stops

To stop smoothly, gradually apply the brakes while simultaneously pulling in the clutch lever. This prevents the engine from stalling and allows for a controlled stop.

9.4. Gear Changes

When shifting gears, quickly pull in the clutch lever, shift to the next gear, and then smoothly release the clutch lever while applying throttle. This ensures a seamless transition between gears.

9.5. Low-Speed Maneuvering

Use the friction zone to maintain control during low-speed maneuvers, such as parking and making U-turns. This allows for precise control of the bike’s speed and balance.

10. The Future of Motorcycle Clutch Technology

Motorcycle clutch technology continues to evolve, with advancements in materials, design, and control systems. Innovations such as automated manual transmissions (AMT), electronic clutches, and advanced slipper clutch designs are shaping the future of motorcycle riding.

Stay informed about the latest advancements in clutch technology to make informed decisions about your motorcycle and riding gear.

10.1. Automated Manual Transmissions (AMT)

Automated manual transmissions combine the efficiency of a manual transmission with the convenience of an automatic. These systems use electronic controls to automatically engage and disengage the clutch, providing seamless gear changes without the need for a clutch lever.

10.2. Electronic Clutches

Electronic clutches use sensors and actuators to precisely control clutch engagement, providing smoother and more consistent performance. These systems can also offer features such as launch control and anti-stall technology.

10.3. Advanced Slipper Clutch Designs

Advanced slipper clutch designs incorporate sophisticated ramped mechanisms and electronic controls to provide even smoother and more predictable performance. These systems can also be adjusted to suit different riding styles and track conditions.

10.4. Materials and Coatings

Advancements in materials and coatings are improving the durability and performance of clutch components. New friction materials, stronger steels, and advanced coatings are extending the life of clutch plates and reducing wear and tear.

FAQ: Understanding Motorcycle Clutches

1. How often should I replace my motorcycle clutch?

The lifespan of a motorcycle clutch varies depending on riding style, maintenance, and the type of clutch. On average, a clutch may need replacement every 20,000 to 50,000 miles. Look for signs of slipping or sticking to determine if a replacement is necessary.

2. Can I adjust my motorcycle clutch myself?

Yes, adjusting a motorcycle clutch is a relatively simple task that can be done with basic tools. Consult your motorcycle’s service manual for specific instructions on how to adjust the clutch cable or hydraulic system.

3. What is the difference between a wet clutch and a dry clutch?

A wet clutch operates in an oil bath, providing lubrication and cooling, while a dry clutch operates without lubrication, offering higher friction but requiring more careful maintenance.

4. How does a slipper clutch improve performance?

A slipper clutch reduces engine braking during aggressive downshifting, preventing rear-wheel lockup and improving stability.

5. What are the symptoms of a worn motorcycle clutch?

Symptoms of a worn motorcycle clutch include slipping, sticking, difficulty shifting gears, and a burning smell.

6. Can I use car engine oil in my motorcycle with a wet clutch?

No, car engine oil is not suitable for motorcycles with wet clutches as it may contain friction modifiers that can cause clutch slippage. Use motorcycle-specific oil that is JASO MA or JASO MA2 certified.

7. How do I prevent clutch slippage?

To prevent clutch slippage, use the correct type of engine oil, adjust the clutch cable properly, and avoid riding with a heavy load or in high gears at low speeds.

8. What is the friction zone of a motorcycle clutch?

The friction zone is the point where the clutch begins to engage, allowing for controlled power delivery.

9. Is it normal for a dry clutch to be noisy?

Yes, it is normal for a dry clutch to be noisier than a wet clutch due to the absence of lubrication. The rattling noise is caused by the clutch plates vibrating.

10. Can I upgrade my motorcycle from a manual clutch to an automatic clutch?

While it is possible to convert a motorcycle from a manual clutch to an automatic clutch, it is a complex and expensive modification that may require significant changes to the drivetrain and control system.

Conclusion: Mastering Your Bike’s Clutch for a Better Ride

Understanding “how does a bike clutch work” is crucial for every motorcycle enthusiast, enhancing your riding experience and ensuring your bike performs at its best. Whether you prefer the control of a manual clutch or the convenience of an automatic, mastering clutch techniques will make you a more confident and skilled rider.

Ready to take your riding to the next level? Explore usabikers.net for in-depth articles, expert advice, and a thriving community of fellow motorcycle enthusiasts. Join our forum, share your experiences, and discover the latest trends in motorcycle technology. Ride safe and stay connected with usabikers.net – your ultimate resource for all things motorcycle!

Address: 801 Sturgis Main St, Sturgis, SD 57785, United States

Phone: +1 (605) 347-2000

Website: usabikers.net